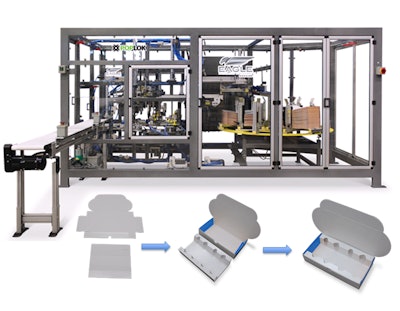

Eagle Packaging Machinery expands their line of tray formers with the PopLok™ Inserter. The new system automates the tedious hand-loading process for placing an insert into a fold-and-tuck-style tray. The PopLok Inserter conveniently loads an insert blank, squarely forms it, and precisely places it into the tray all in one compact machine.

The insert, highly suitable for the medical industry, serves to ensure that fragile tray contents are separated and neatly secured for shipping.

The PopLok Inserter delicately handles corrugated and chipboard material to consistently produce a quality finished product. The careful handling process certifies that high gloss graphic aesthetics are not marred in any way for high-standard retail requirements. Because the PopLok Inserter does not use a mandrel, operators can also perform rapid changeovers without tooling.

Other differentiating features of the PopLok Inserter are dependable 24/7 operation, world-class components like SMC and Tolomatic cylinders, Omron or Allen Bradley PLC, and a 7” color touch screen HMI allowing for user-friendly operation.