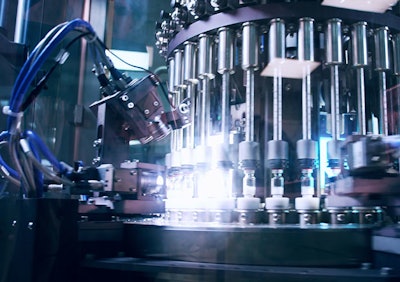

High-value pharmaceutical and biological therapies, including vaccines, antibodies, proteins, blood plasma, etc., often require freeze drying, or lyophilization, to lengthen their lifespan. The process safely removes water from the sensitive products, enabling then to be stored until they are needed, at which time they can be reconstituted by replacing the water.

Equipment that can minimize human intervention during lyophilization can help prevent possible product contamination. As advanced treatment therapies continue to become available for patients, it’s understandable that the market for lyophilization equipment is predicted to reach nearly $2.66 million by next year, according to research from MarketsAndMarkets.

On June 7, ASTM International announced a proposed standard that aims to promote a shared understanding of the science and engineering behind pharmaceutical freeze drying. The proposed standard (WK63507), is being developed by ASTM’s committee on the manufacture of pharmaceutical and biopharmaceutical products (E55).

According to ASTM member Arnab Ganguly, uncertainty over the best practices in these areas of freeze-drying operations can lead to delays resulting from lengthy internal debate over what constitutes best methods. Industry-wide standards can reduce time lost in unnecessary debate over best practice protocols.

“While process understanding in pharmaceutical freeze-drying has improved, process design has seen little change since inception,” says Ganguly, Technology Manager of IMA Life North America Inc. “For example, there is no known standard related to use of process instrumentation applied to freeze drying.”

ISTA believes that development scientists, validation and operations engineers, technicians, and operators in the biopharmaceutical industry would benefit most from this new information.

The next meeting of ASTM International’s committee on the manufacture of pharmaceutical and biopharmaceutical products takes place October 22-24 at Purdue University, West Lafayette, IN.

For more information on lyophilization developments, click on the blue-colored headlines at this link.