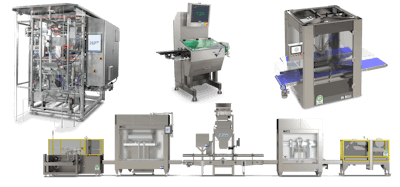

Running in the Paxiom Group booth is the V25 bulk weigh filling system, a full turnkey system that includes automated case erecting, bag inserting, bulk weigh filling, bag uncuffing, and case sealing. The system includes the Boxxer case erector, which can be supplied with tape or glue; the new BI 600 bag inserter, designed to automatically dispense rollstock film, then cut, seal, and insert the bags into cases, trays, and bins; the PrimoLinear V-25 bulk weigh filler; the BU 600 bag uncuffer, which is designed to uncuff a filled bag from a corrugated case and fold the bag in over the top of the product; and a case closer that can be equipped with glue or tape and can feed directly into the company’s robotic palletizing system.