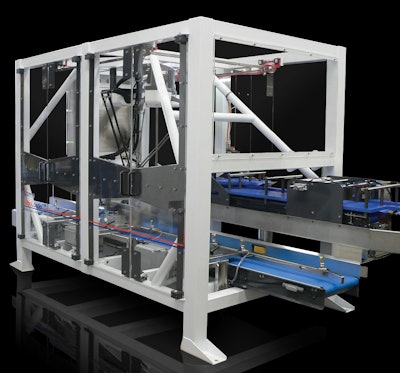

The machine designers at Pro Pack Systems, a manufacturer of end-of-line packaging machines, had packaged salad producers squarely in mind when they recently introduced a machine called the RoboLoader. Flexible, intuitive, and competitively priced, it’s also very robust and is constructed from corrosion and stain-resistant powder-coated or electropolished stainless steel. That makes it highly suitable for a washdown environment, which is so important to packaged salad producers, who are understandably in favor of a machine designed to facilitate sanitation routines.

Even more advanced is the RoboLoader’s robotic package handling technology and the contributions made by its sophisticated controls. A delta-style robot from Codian Robotics powered by a B&R control system are central to the RoboLoader’s flexible functionality. The robotics platform can handle a wide variety of package styles, pack patterns, payloads, and speeds, reducing the time and cost of production changeovers. Whether the operator is running a bag line or a clamshell line, the case packaging equipment is very similar in operation. Pack patterns can simply be selected from a dropdown recipe menu on the HMI. Changeovers involve nothing more than switching out guide rails, which involves no tools at all. This greatly eases the training burden on machine operators and maintenance staff.

The RoboLoader takes a unique approach when it comes to robotics. The open architecture of the Codian robotic solution allowed Pro Pack to choose control components according to specific design needs rather than being bound to proprietary products—as is often the case with off-the-shelf robots.

Pro Pack selected a B&R Power Panel to unite PLC and HMI functionality in a single device. The Power Panel allows integration of the RoboLoader’s motion control technology into the same system used for the rest of the machine. Since Pro Pack uses robotics to handle a range of tasks throughout the line, this not only greatly simplified the design but the troubleshooting process as well. Compact, multi-axis servo drives from B&R control the machine’s motion and communicate via the real-time industrial Ethernet Powerlink protocol. RoboLoader’s architecture requires less wiring and cabinet space than traditional solutions, affording significant cost savings in hygienic environments such as salad processing.

Using B&R’s Automation Studio development environment, Pro Pack creates highly modular code that makes manufacturers in the food industry even more efficient when using the RoboLoader. This approach produces higher quality software with vastly improved long-term sustainability, thereby decreasing the instances of programming errors, preventing machine downtime, and reducing the time and expense of software development. “Using Automation Studio helps us substantially improve integration of machine and robotic control across the line,” says Zurlinden. “It makes life easier not only for Pro Pack engineers but for the machine operator as well.”

When a standalone robot is placed in a work cell, the level of integration is often very limited and may entail multiple electrical cabinets with various electrical components and a dedicated robot HMI. This limits the developer’s ability to provide operators with useful diagnostic information. With a truly integrated approach, on the other hand, alarms and errors associated with the robot are handled in the same way as any other axis for consistently simple diagnostics across the board.

“Our next venture will be robotic palletizing for the salad industry. That market poses challenges for conventional palletizers due to the spatial limitations of their existing production lines, but we are confident that, with B&R as our partner, we’ll soon be shaking things up with an innovative solution,” says Zurlinden.