With a footprint measuring just 9’x8’ and a capacity for loading a variety of bagged products into multiple case sizes at speeds to 10 cases/min, the new TL-10 robotic top-load case packer from Sabel Engineering represents the latest in servo-based packaging machinery.

The most critical function of the machine is the precise positioning of bags for loading into the case. This is accomplished by using three separate servo conveyors, each driven by a B&R Acopos drive. B&R USA partner PacMation helped with training and installation.

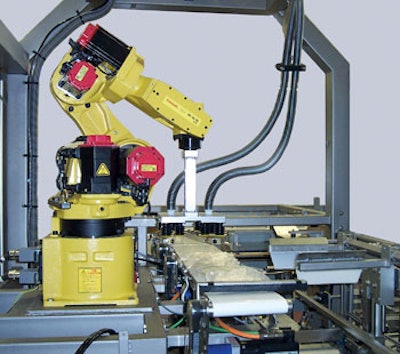

Conveyor one guarantees spacing while conveyor two indexes bags forward to form groups of four. Conveyor three quickly advances the four bags to a precise position from which a Fanuc robotic arm, integrated into the top-loading system, can pick them.

Also crucial is the presentation of the erected case at the loading station. Once again, B&R Acopos servo drives, combined with Bosch Rexroth CKR Series actuators, provide smooth and accurate positioning of the case for loading.

“We liked the CKR Series actuators because they’re compact and because they have a double-rail construction that is good for handling heavy loads,” says Hitan Patel, controls and R&D manager at Sabel.

A B&R Power Panel PP220 with integrated I/O and 10” touch screen serves as the TL-10’s controller. It governs logic, motion, and HMI on the system. With Ethernet Powerlink, a real-time Ethernet-based communications protocol, positioning information is sent from one servo drive to the other via standard Ethernet cables. Cycle times of less than 400 microseconds allow for very fast updates of information among the servo drives. This Ethernet connectivity also eliminates the need for additional encoder wiring between the drives, leading to simplified wiring overall and less time spent on troubleshooting.

The robotic pick-and-place end effector uses vacuum to grip the bags. Sabel elected to use the B&R XV valve controller module to simplify the connection of the pneumatics to the machine.

Among the controls features on the TL-10 most appreciated by Patel is the integrated logic/motion/HMI controller.

“The integrated controller is much simpler from both a hardware and software standpoint,” says Hitan. “You don’t have to think about drivers for communication between logic control and HMI. And a single software program is applied for logic, motion, and HMI.” Also notable is that B&R’s Automation Studio software development tool builds on the standardized PackML language developed by the OMAC Packaging Workgroup.

All five servo axes of motion described above—three for conveyor belts and two for case erecting—are synchronized with the movements of the six-axis Fanuc robot. The controller governing the robot communicates with the B&R controller along a B&R X20 I/O system. “This is what keeps the robot’s motion synchronized with the positioning belts of the Sabel machine,” says Patel. —Pat Reynolds