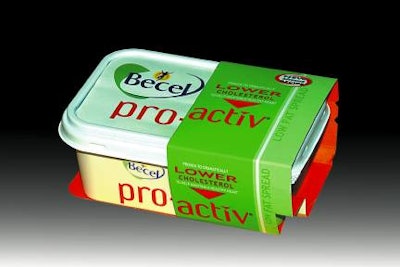

Unilever spokesman Richard van der Eijk notes, “Pro.active is an innovative product with the benefit of reducing blood cholesterol levels. In order to explain to the prospective buyer the product’s characteristics and benefits, more printing surface was needed on the package. The addition of a carton sleeve and a booklet allows much better communication with consumers.”

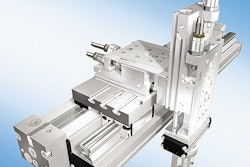

Unilever evaluated its equipment supplier/engineering options and awarded the cartoning system contract to Kliklok-Woodman. Kliklok-Woodman built three complete packaging systems for installation at three different Unilever plants in Europe. The lines include Servo IPTUs (Intelligent Product Transfer Units) that feed the filled, membrane-sealed, lidded margarine tubs into specially designed conveyor systems, enabling accurate placement of informational booklets into the indented tub lids. The servo-driven booklet feeder is integrated into the infeed conveyor of KW’s Prima end-load cartoner, which was customized to conform to the mechanical and electrical specifications of the application.