From being stuck inside a truck or plane in hot weather during drug distribution, to warm summer days on the kitchen or bathroom shelf in the consumer’s home, packaged pharmaceuticals are under attack. Oxygen and moisture are the enemies, and the collective efforts of materials scientists and the packaging are mounting the defense.

Three trends boost the need for effective oxygen absorption solutions, both active and passive:

• Drug manufacturers want increased shelf life for their formulations, to optimize costs in manufacturing and distribution.

• The U.S. Food and Drug Administration (FDA) wants longer shelf life, with full potency, for the drugs they regulate.

• A higher proportion of molecules in the drug pipeline are in Classes II and IV. These classes of molecules are often formulated in such a way as to make them more sensitive to oxygen.

The Healthcare Compliance Packaging Council’s recent study, "Prescription Packaging In-Use Stability Study, " pointed out possible adverse effects daily exposure to moisture and oxygen can have on non-coated tablets stored in traditional amber pharmacy vials, plastic bottles and low-barrier blister films—right in consumer’s homes.

The study tested these packaging formats along with PVC/PVDC and Aclar® blisters under normal usage conditions, higher humidity levels and higher temperatures, and found that significant physical changes can occur in tablets when distributed in low barrier or multi-use containers in as little as 30 days.

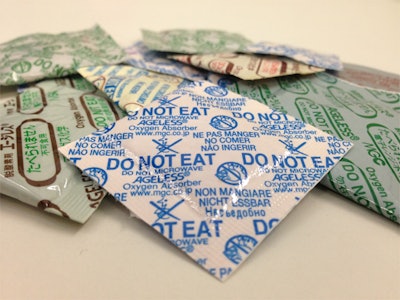

“Innovative Oxygen Absorption Packaging Solutions,” was the title of an informative Innovation Stage presentation at Pharma EXPO 2015 from Atsushi Inoue, R&D Manager at Mitsubishi Gas Chemical Company.

Oxygen absorption has been a product focus for Mitsubishi, and although many of its resulting offerings are intended to keep foods fresh without preservatives, some of these products are suitable for pharmaceuticals. And its oxygen absorbers are designed to not only be placed inside a package, such as sachets and canisters, but also to be part of a multilayer structure.

In May of this year, the company introduced an advanced-material multilayer plastic syringe and vial for parenteral pharmaceuticals. OXY-CAPT™ brings together the best properties of plastic and glass containers through the combination of oxygen absorption and COP (cyclic olefin copolymer) high-barrier layers. The container is manufactured with three layers: water barrier layer—COP resin; oxygen barrier layer—new oxygen absorbing layer; and drug contact and water barrier layer—COP resin.

Oxygen not welcome

The company has developed a special iron-based oxygen-absorbing resin, which does not need moisture or activation sequences to absorb oxygen, according to Inoue. Moisture and odor absorption can be also be added for this multi-function packaging solution. It can be used in blow molding, film, sheet molding and in laminates. AGELESS® is the umbrella name for the technology.

PharmaKeep® is Mitsubishi’s brand name for its oxygen-absorbing desiccant for low-moisture products (pharmaceutical pills and powders). It’s a special type of absorber that works on both oxygen and moisture. Conventional oxygen absorbers require moisture for oxygen absorption, creating a potential problem for dry medicine.With the older absorbing method, there is generally moisture built into the package.This moisture helps the absorber to begin absorbing, but it also transfers a small amount of moisture to the product it is protecting—bad news for pharmaceutical products, which must be kept dry.

PharmaKeep’s dual absorption of both oxygen and moisture at the same time are what makes it so useful. PharmaKeep can prevent oxidation and hydrolysis in pharmaceuticals, and also helps protect oxygen-sensitive medical devices and equipment.Both sachet and canister styles are available for use with any number of different sized bottles and containers.

OxyVanish™ is specially designed for use with pharmaceutical and nutraceutical products.

• Activates using the natural moisture of a product with mid to high water activity levels.

• Prevents degradation of oxygen-sensitive products.

• Extends product shelf life.

• No need for canisters or sachets.

• Can be used with pharmaceutical and nutraceuticals in the following forms: pills, tablets, capsules, and powders.

Stability studies using the OxyVanish absorber in plastic bottles were tested with EPA supplements, versus EVOH barrier and regular HDPE, according to Inoue. The absorber kept the product fresher (retention of vitamin E content) and with less “fish-oil” smell than the other two constructions, for up to a year.

OxyBarrier™ builds oxygen absorption right into a multilayer drug bottle, to stop oxygen permeation. Very low OTR in constructions using the barrier (outer to inner: HDPE, adhesive, EVOH barrier layer, adhesive, HDPE) allows for use of a smaller oxygen absorber.

It’s all about keeping the oxygen out, for the amount of shelf life needed, in a form that packagers can afford, and consumers will use.