This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

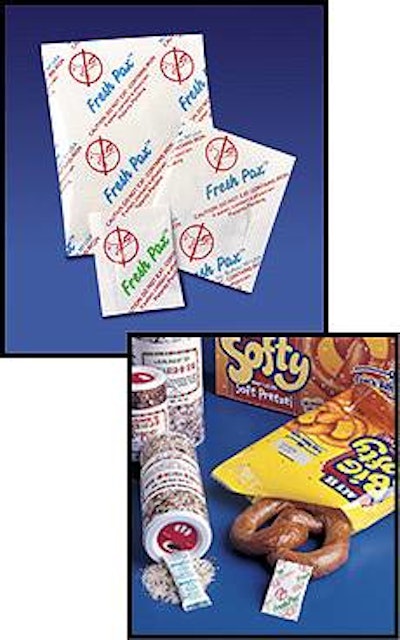

Produced in packet form using food grade ingredients, FreshPax irreversibly absorbs oxygen inside sealed packaging to less than 0.01% and maintains this level.

FreshPax packets have several distinct advantages for your product packaging:

* Extends shelf life

* Prevents growth of aerobic pathogens and spoilage organisms, including molds

* Eliminates the need for additives such as BHA, BHT, sulfur dioxide, sorbates, benzoates, etc.

* Use with or without gas flushing/vacuum packaging to absorb virtually all oxygen and absorb any oxygen that may permeate the package

* Available in spool or fan-folded for automatic dispensing

* Increases stability in oxygen sensitive compounds

Typical applications include:

* Breads, cookies, cakes, pastries

* Nuts and snacks

* Candies and confectioneries

* Coffee and tea

* Whole fat dry foods

* Processed, smoked and cured meats

* Cheeses and dairy products

* Flour and grain items

* Fresh and pre-cooked pasta and noodles

* Birdseed and pet food

* Artwork preservation

* Pharmaceuticals and vitamins

* Medical diagnostic kits and devices

Examples of FreshPax Benefits:

* Significantly improves keeping qualities of polyunsaturated fats and oils

* Helps retain fresh-roasted flavor of coffee and nuts

* Prevents oxidation of spice oleoresins present in spices themselves and in seasoned foods

* Prevents oxidation of vitamins A, C and E

* Inhibits mold in natural cheeses and other fermented dairy products

* Delays non-enzymatic browning of fruits and some vegetables

* Inhibits oxidation and condensation of red pigment of most berries and sauces

Package requirements for successful use of FreshPax

FreshPax has been found to be effective when used with many kinds of packaging materials including EVOH and PVDC. Some important considerations to keep in mind regarding certain types of packaging include:

* Adequate barrier should be used - Plastic film must be checked for its oxygen permeability

* Hermetic seals are essential - Non-hermetic seals reduce shelf-life by using up oxygen absorber capacity prematurely

* Package geometry - The package must be designed so as to allow free circulation of air around the product

It is recommended that application tests with actual materials and equipment be conducted before using and specifying FreshPax. This includes determining the water activity of the product as nearly as possible, at what temperature the product will be packaged, and specifications of the packaging film.