This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

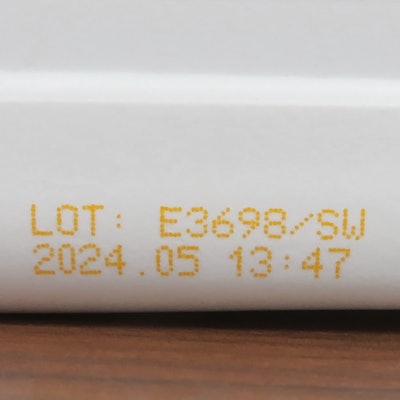

The V425 ink, manufactured by printing, coding, and marking products Videojet, offers a fast dry time and is formulated for improved uptime, especially in hot, harsh, and humid environments. With its yellow pigment, the ink provides contrast on dark and light colored substrates. The ink’s adhesion and chemical resistance make it well-suited for printing on rigid plastic automotive fluid containers and metal parts. It is resistant to automotive fluids, including motor oil, two-cycle engine oil, tire cleaner, fuel injection cleaner, leather conditioner and antifreeze/coolant. V425 is also resistant to acetic acid, ammonia, mineral spirits, propylene glycol and vegetable oil.

V425 ink adheres well to other substrates including acrylonitrile butadiene styrene (ABS), aluminum, polystyrene, polyvinylchloride (PVC), polycarbonate, steel and nylon. Its contrast and transfer resistance make this ink ideal for marking both black and white wires and cables.

Sherry Washburn, Videojet Business Unit Manager for Supplies, said, “Plastic, wire and cable, and parts of all sizes and substrates need consistent, high-resolution codes that can withstand harsh environments. With our wide portfolio of inks, Videojet remains committed to helping customers select the right ink to meet their unique application needs.”