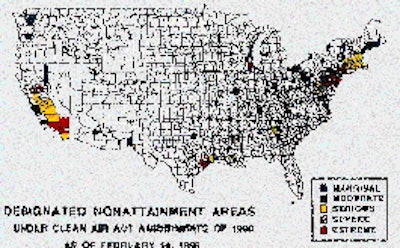

The domino theory is back. You remember the concern in the U.S. in the 1950s and '60s about country after country in Southeast Asia falling to Communism. Fast-forward to 1997. The domino theory now describes what may happen to packaging prices as suppliers downstream pass on increasingly jumbo price increases resulting from meeting new ozone and particulate matter (PM) air pollution rules proposed by the Environmental Protection Agency (EPA). Here is how the packaging domino could thud. Look at your packaging supply chain as far as it goes and count the companies that have a material input to the final barrel, box, foam or wrap. Each one of those companies may have to swallow new transportation, energy and manufacturing costs as a result of the tighter ozone and PM rules proposed by the EPA last November. Those increased costs would come from efforts to control factory emissions of volatile organic compounds (VOCs), nitrogen oxide, sulfur dioxide and other chemicals. Material suppliers will also pay higher electricity costs because of emission control investments by electric utilities. Some suppliers may find their plants in areas where more expensive reformulated gasoline has been mandated. As all these costs are added on to material prices all the way up the chain, the price increase could swell by the time the finished packaging arrives at the loading dock. It is not yet certain whether the last domino will slam down, or land more daintily. That depends on the number of metropolitan areas suddenly thrown into ozone or PM "non-attainment" areas by any new standards. Even if the agency decides to go with the tighter 0.08 parts per million (ppm) ozone standard and the new PM2.5 standard (regulating fine particles for the first time), Congress could force the EPA to back off. If Congress and the courts let those new standards stand, states would be required to submit state implementation plans (SIPs) by 2000 for ozone, and 2002 for particulates. Compliance deadlines for companies would come two or three years later. Not just for stratospheres The proposed ozone change appears to be the more significant threat. The American Petroleum Institute (API) estimates there are currently 66 ozone non-attainment areas (273 counties) versus about 82 PM10 non-attainment areas (84 counties). Al Mannato, senior regulatory analyst for the API, says tightening the current 0.12 ppm ozone standard to 0.08 ppm would multiply the ozone non-attainment areas to 184, which translates into 603 counties. PM counties would reach 287. The EPA's estimates are less dramatic. The agency says the new ozone and PM standards would affect 335 and 167 counties, respectively. "These proposed standards are just starting to become an issue for residential and industrial consumers," says Quin Shea, director of environmental affairs for the National Mining Assn. Some of his member companies mine iron ore. They are currently unaffected by the PM10 (coarse particles) standard. But Shea says mines that are co-located with ore processing plants will probably run afoul of the PM2.5 standard. Emission control investments made by the mines will end up larded in the costs of the ore, which steel mills will have to pay. The steel manufacturers are definitely in line for major capital investments to comply with the PM2.5 standard. They may also have some VOC control costs. Pass it on Those and the increased ore costs will be passed along to the next domino, the steel drum manufacturers. Dana Worcester, technical director for the Assn. of Container Reconditioners, estimates that a tighter ozone standard will result in about 100 member companies paying a total bill of $13 million to $20 million in compliance costs. That's in addition to the cost of complying with the new PM standard, which is harder to estimate. That is only one domino chain. There are plenty of others, where the final product is plastic or paper packaging. The EPA estimates that in the year 2007, when both new requirements are finally phased in, all industry-that is the total for all Standard Industrial Classifications (SIC codes)-will pay annual compliance costs between $7.9 billion and $10.2 billion. Ozone is the result of chemical reactions of VOCs, nitrogen oxides and oxygen in the presence of sunlight, and generally at elevated temperatures. High ozone levels are associated with respiratory disease. Particulate matter comes largely from combustion sources like power plants or large incinerators. But it is also the dust created by mining and construction operations. When she announced the proposed tightening of the standards last November, EPA administrator Carol Browner said they would result in 133 million Americans, including 40 million children, breathing cleaner air. How it's measured The current EPA limit is 0.12 ppm. An excess occurs when ozone is above that level for one hour or more. The EPA's November proposal calls for a tighter 0.08 ppm standard. But it would be eased a bit since an excess would be defined as a level above 0.08 ppm when readings for an eight-hour period were averaged. The particulate matter standard would keep its current restriction on particles 10 microns or smaller and add a new standard on particles 2.5 microns or smaller. The new "fine particle" standard would mean that smaller volumes of PM per cubic meter would have to be regulated. Packagers who want a glimpse into the future might want to look back at how suppliers have reacted to the 0.12 ppm ozone standard. Dale Arthur, general manager of Styrotek, Inc. (Delano, CA), says his company is not in a non-attainment area. Not yet. But he could read the writing on the wall. Styrotek manufactures 12 million foam boxes each year that are sold in a four-month period between July and October to local grape growers. The company uses pentane as its blowing agent. In 1994, Styrotek spent $250ꯠ on a pentane collection system, including a retrofitted boiler. "The year after we spent that money, the cost went into our calculations for box prices," says Arthur. Paper is hit, too A similar scenario played out further up the supply chain, with two International Paper (Purchase, NY) plants in Pennsylvania. One is a soda process pulp mill in Erie, the other a paper mill in Loch Haven. Pennsylvania, like other states, had to put together a SIP that attempts to control ozone levels for its non-attainment areas. The SIP prescribed "Reasonably Achievable Control Technology" or RACT. Jeff Shumaker, manager of air programs for International Paper, says the SIP required controls be put on any boilers rated 250 million BTUs/hour or more that burn fossil fuels. The idea was to reduce emissions of nitrogen oxide from those boilers. Low-Nox burners were put in the Erie mill as a result. Shumaker declines to specify what the controls in Erie cost. He adds, "But I can say generally that if companies want to stay solvent, then yes, there is either a cost reduction elsewhere in the company that offsets the expense of a Low-Nox burner, or some kind of pass-through of those costs to the customer." The EPA has been busy collecting public comments on the November proposal. One industry source says that environmental groups have run a very aggressive campaign to get their members to flood the agency with supportive comments. The EPA faces a July 19, 1997, federal court-imposed deadline for announcing new ozone and PM standards. Is rationale scientific? Industry criticism has focused not so much on increased manufacturing, transportation and electric costs but rather on what every SIC code representative under the sun has described as a severely lacking scientific rationale for both new standards. For example, testifying at public hearings in Boston in January, Maureen Healey, director of federal environment and transportation issues for The Society of the Plastics Industry, said, "For both ozone and particulate matter, EPA has not adequately considered confounding factors, such as weather or other pollutants." But whatever the scientific reality, it has taken a back seat to politics, as is often the case in Washington. A perception quickly took hold on Capitol Hill that the proposed ozone and PM standards were radical environmentalism run amok and, perhaps more importantly, that they would end up clobbering "small business," a lobbying force which can move legislative mountains that the Fortune 500 can only dream about. In Boston, Healey emphasized that the majority of SPI's members are small businesses. Eighty percent have fewer than 100 employees. She went on to complain that the EPA should have done a regulatory impact analysis on small business as required by the Regulatory Flexibility Act of 1980. Small fights large That law requires an economic impact analysis if a proposed rule has "a significant economic impact on a substantial number of small entities." The EPA declined to do that analysis, reasoning that it is not the proposed ozone and PM standards that will affect small business. Rather it will be the SIPs that do the damage. The EPA's refusal to do an RFA analysis has political implications. Under the Small Business Regulatory Enforcement Fairness Act of 1996, economic impact analyses are judicially reviewable. Sens. Christopher Bond (R-MO) and Dale Bumpers (D-AK), the ranking members from each party on the Small Business Committee, wrote to EPA's Browner in January, terming her reasoning for refusing to do an RFA analysis "simply not persuasive." Complaints about faulty science and insensitivity toward small business have found other open ears on Capitol Hill. By mid-February, key Republicans like Sen. John Chafee (R-RI) had heard enough. Chafee is a particularly pivotal legislator because he has good environmental credentials and he also chairs the relevant committee, the Senate Environment and Public Works Committee. "With the tighter standards, you're going to find a revolt against the Clean Air Act," he said the evening before the first hearings on the issue in his committee.