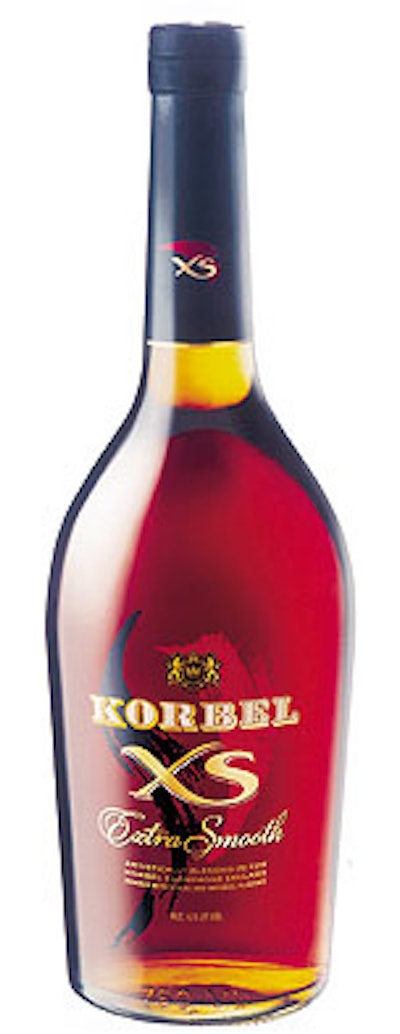

The champagne cellars of Korbel have been producing brandy since 1889, but this year the Guerneville, CA-based company has introduced two new products: Korbel VSOP and XS. While it was designing the graphics for its new products, it also redesigned the decorating for what it calls its Classic brandy.

Classic brandy underwent a label redesign about four years ago, a redesign that produced what Korbel president Gary Heck calls “a pretty nice package.” However, he says that, in the meantime, decorating technologies have improved. “The labelers are better, and the gold colors are much better, so we decided to upgrade the Classic line while we developed labels for the two new products.”

One of the new products is VSOP, a 90-proof brandy that Heck believes will appeal to those that favor richer cognac flavor.

“At the same time, we wanted to create a product for younger people looking for more fun drinks,” Heck says. That’s why XS (extra smooth) was developed. It’s a brandy flavored with spices like nutmeg and vanilla that should appeal to people who enjoy mixed drinks. Heck’s son Aaron worked with designer Fred McDaniel of HKA (San Francisco, CA) to design the clear pressure-sensitive labels for XS.

The same graphics team also developed the rich gold look for VSOP and did the redesign on Korbel Classic. The VSOP bottle is distinguished by its lavish use of gold hot stamping and by the medallion on the shoulder (see sidebar). Korbel Classic uses an extra front label with the signature of Gary Heck that’s duplicated as part of the neck label.

“We wanted something different for XS, and boy, did we get it,” Heck says. Applying p-s labels is a totally different technology for Korbel brandy, particularly with a tapered bottle. In fact, the XS bottles aren’t labeled on-line with filling. Korbel takes the bottles to one of its wineries that uses p-s labels and decorates the bottles there before carrying the bottles back to the distillery for filling and packaging. If volumes of the product attain a certain level, the company will simply add a labeler to apply film p-s labels.

The XS label for most sizes is produced by Collotype Labels (Napa, CA) using 2-mil Optiflex polypropylene film from Flexcon (Spencer, MA). It’s printed offset in three colors, plus a screened gold color and hot stamping. The label is finished with an ultraviolet gloss varnish. The labels for VSOP and Classic come from FP Label (Napa, CA) using 60# cast-coated paper from Germany. They’re printed offset in five (VSOP) or eight colors (Classic), plus both spot aqueous and dull UV varnishes. These labels are also hot stamped and embossed before die-cutting.

Each bottle also combines a plastic TE capsule with a printed paper neck label, all from FP Label. All back labels are paper. For smaller sizes (50-, 200-, and 375-mL), most brands use p-s metallized paper labels from LSK Labels (El Dorado Hills, CA).

Behind the times

Heck candidly admits that Korbel had been outflanked by some of its brandy competitors. “We were behind the times, and we needed to become more competitive,” he says. Several other producers have three or four different flavors or varieties, while Korbel just had its Classic. “We had our three facings on store shelves, but some competitors were now getting nine.”

However, Korbel had no track record on new brandy products, so it was really rolling the dice on what volumes to expect from the new products. With VSOP, its price and a limited supply of product will control the sales volumes. But with XS, the company has no such controls.

“The reaction to the new products has been absolutely tremendous,” Heck enthuses. “Everyone we sell to has been extremely positive about the label changes. Retailers tell us that VSOP is a very attractive package on the shelf and that it looks as high-end as the price we’re charging for it.” VSOP sells for $3 to $5 more than a 750-mL of Korbel Classic, which retails for $10 to $13.

XS, which sells for about $2 more than Classic, has been a pleasant surprise to Korbel. “Everyone we show the product to says ‘I’ve got to have it in my store!’” says Heck. “They tell us that it’ll be a fun product to sell because the packaging will grab shoppers’ attention. We offer it in a three-case rack that, as a floor display, generates a lot of attention. The reaction has been phenomenal. We’ve already had to make a second production run, just for the introduction.”

Labeling challenges

As excited as the company is about the success of the introduction, Heck admits that the decorating process has been a learning experience. When asked if the intricate die cuts make these labels more difficult to apply, Heck laughs with a hearty, “Absolutely!”

Noting that designers often don’t understand the effect of intricate shapes on automatic labelers, Korbel needed expertise both at the drawing board and in the plant. Where the front label on both Classic and VSOP have the family crest die cut above a straight edge, “application is tough, so we have to run the lines a little slower,” Heck says. “It’s important that where the crest sticks up we have more of a round cut; otherwise, the label will rip easily.” The round cut isn’t evident in the photos shown here.

Because the label shapes have all changed, Korbel had to buy new change parts for its glue-applied labels for Classic and VSOP. For each product, the labeler applies four separate labels: two front-panel labels for Classic, along with a back label and a wraparound neck band that coordinates with the T-E capsule; for VSOP, one front, one shoulder medallion, the back, and the wraparound neck band. While the neck band isn’t new, using a printed version is an upgrade.

The slowdown of the labeling is only on start-up. “We begin our run maybe 10-percent slower than before,” Heck says. “After awhile, we can bring the line up to our normal speeds.”

Moving to half-packs

In response to comments from retailers, Korbel is moving much of its production into what it calls “half-packs,” shipping cases that hold one-half the normal quantity. “We really felt that retailers would be facing a lot of broken-case charges from distributors because some stores wouldn’t want to try the new products in conventional full-case quantities,” Heck explains.

For VSOP, filled in sizes up to 750-mL, each size is packed in half-packs (e.g., six 750-mL bottles instead of 12). For the XS product, the 750-mL is in a traditional 12-count case, but all other sizes are offered in half-packs. This change has been so popular that Korbel will be treating its Classic brandy the same way as XS. “This change has really proven to expand distribution of our smaller sizes,” Heck says.

Finally, having three different brands lets Korbel move into cross-merchandising. “Along with all the regular point-of-sale materials and racks, we’ll be attaching 50-mL bottles of VSOP and XS onto our regular Classic bottles via a neck hanger,” Heck says. “And we’re doing dump bins for our 50-mL bottles to sell at $1 per bottle. No one makes money on that, but the goal is to get people to taste our products.

“If consumers respond the way the retailers have, we’ll be very pleased.”