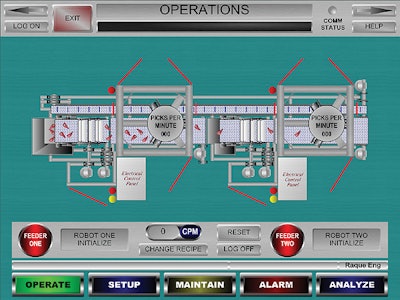

A new generation of tray filler that uses robotics demands a new generation of human-machine interface. CTC Parker Automation’s InteractX® touchscreen panel is used on Raque Food Systems’ latest tray filler. The Robotic Tray Filler features 120 tray/min/lane robotic placement of asymmetrical frozen foods such as chicken wings. The Microsoft Windows-based HMI is getting rave reviews from Raque’s director of automation engineering Jerry Barnes.

“InteractX is a premium product,” says Barnes. “It is much more flexible and adaptable to customers that want more power, more graphics, more SCADA, more data management. We can put together view screens a lot quicker, yet it also permits better customization for customers.”

Barnes points out that the HMI is the cornerstone of the machine’s troubleshooting and diagnostics capability. He is relying on the advances in the HMI over the previous generation to “vastly improve” machine troubleshooting.

One such feature is the on-screen availability—in PDF format—of an operator manual, which means it can never be misplaced. “If an operator has even a decent-looking picture of an adjustment in front of him, half the battle is won,” says Barnes. Self-diagnostics will warn of current and impending problems, he adds.

Barnes expects the data acquisition to “vastly exceed” the capabilities of CTC’s previous version, which had recipe management, historical trending, and machine management modules. InteractX replaces the CTC Powerstation versions Raque has used since 1994.

It also offers sizzling graphics.

“The graphical power is excellent,” says Barnes “and it’s a lot easier and faster to develop the screens. It is several orders of magnitude better than what we used before—and it leapfrogs the competition.

“We can offer more diagnostics with less overhead work and development work on our side,” adds Barnes. One feature he likes is Tool Chest, which allows a Raque engineer to develop a standard design motif that can be accessed and used by other engineers in the group. As a result of these time-saving features, he expects the HMI’s software will “definitely knock 30 percent off the HMI development time.

“The HMI provides a wide open canvas for us and our customers,” says Barnes. “More and more customers want connectivity to plant data management systems. InteractX will be an important player in giving us the flexibility to meet that need.” That’s crucial because Raque’s customers can range from mom-and-pop operations to major corporations.