This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

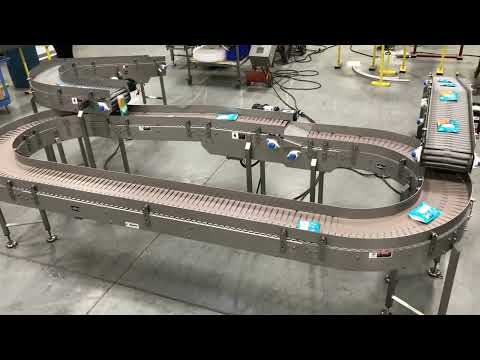

The fixed position 8 in. wide by 25 ft long table top conveyor employs two 90° curves to shape the system in the customer’s required footprint, feeding a downstream case packer ahead. An adjoining 13 ft straight running portable conveyor can be wheeled into place, pin-locked to the fixed main line, and product sent to an alternate packing destination when required.

Just prior to the first curve, a manual product divert gate was installed to transfer product to the desired packing area. This video demonstrates how the manual divert is easily moved into and out of position. Multi-Conveyor’s 1:2 (one-to-two) diverts are used to divide product into two separate lanes of travel include gates, paddles, or guides that can be activated manually or automatically using programmable logic controls.

A cost-effective pin-in-place interlock marries the conveyors. The connecting straight running section is on 6 in. diameter castors for portability. This gives the customer flexibility to move the conveyor out of production, allowing operator access to other critical functions.

The wash down conveyors include slotted cleanout holes and bolted construction with continuous welds. In this case, the motors and reducers were not required to adhere to wash down specifications.