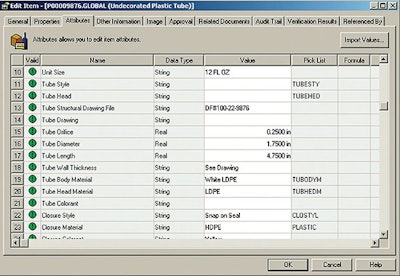

To speed new product introductions to all these markets as efficiently as possible, the company in September ’02 employed a new software program from OSIsoft. Called ProcessPoint PDM (product data management) Editor, the software provides several key benefits.

One is real-time data that enables each of the manufacturing sites to see Alberto Culver’s product and package specifications online. That visibility and shared knowledge ultimately helps Melrose Park, IL-based Alberto Culver speed products to market with real-time access to product specifications as they’re developed and approved.

All manufacturing sites gain visibility to packaging and product specifications as the specifications become approved at the centers. Each location can log into the corporate database and pull the product information needed to assess commercialization capabilities and then determine if they can support a new product initiative.

Once packaging engineers and chemists in the design centers complete the material specifications they can e-mail PDF files of the specifications to the suppliers to help the suppliers move quickly into converting materials for product launches.

Another benefit is that quality improvements come from standardized specification template designs. Defining global quality requirements into every specification template was an important step to make sure suppliers were clear on defined customer needs. Globalization efforts for raw material and packaging specifications were standardized with one set of common specification templates with both English and metric measurements.

PDM Editor has also increased efficiencies by expediting specs for suppliers’ bid packages and the enhancements that came from having a Web-based specification system. That enabled Alberto Culver’s Global Procurement Organization to reduce cycle time on preparing regional and global bid packages. Suppliers now gain visibility to specifications online. According to the company, the days of sending out hard copies of specifications in three-ring binders to suppliers are over.

Alberto Culver estimates that cycle time to complete bid packages have been cut by 50%, helping its Purchasing Organization to realize savings six to eight weeks sooner. That saves the company an estimated $1.5 million on global bids that have been generating over $10 million in annualized savings.

By collaborating with suppliers, and by being involved up-front in the co-creation of new packaging material specifications, Alberto Culver has increased turnaround time to get specifications completed and approved. The suppliers can now review, accept, and approve specifications online.

ProcessPoint includes the server, which acts as the central repository of data; client software used to access and configure the data, and which may be downloaded from the Web; a template editor that enables data to be displayed for different users, and an administration tool used to configure the server. Process Point PDM is installed and stored on an SQL server behind a firewall in a central location at the company’s headquarters.

ProcessPoint PDM Editor also links into the company’s PRISM Enterprise Resource Planning (ERP) system. Formulas and batching instructions from the PDM system are uploaded automatically once they are approved.

The PDM software also works with palletizing data managed by Alberto Culver through a program from CAPE Systems. CAPE palletizing software is used in all of Alberto Culver’s design centers to create efficient pallet patterns for new products. “We are able to upload CAPE files into our ProcessPoint PDM editior and attach these CAPE files to our packaging bills of materials. Data transferred into our PDM is then uploaded into our warehouse management systems, and is helping us to move product to retail customers,” says Curt Funke, divisional vp of global purchasing and packaging engineering for Alberto Culver. —JB