This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

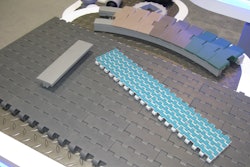

The SCC-15-SS Screen Classifying Cutter from Munson Machinery Company, Inc. features a proprietary rotor design comprised of cutter bits attached to a helical array of staggered holders called “interconnected parallelograms,” that continuously cut and crush oversize materials against twin, stationary bed knives.

Unlike high-shear cutters that rotate at high speeds, the high-torque cutter is equipped with a direct-coupled, gear-reduced drive that rotates the shaft at speeds down to 10 RPM to cut or crush tough materials using low shear, and/or to minimize fines when cutting friable materials.

The cutter bits, which are available in stainless steel, tool steel and tungsten carbide, can be slid onto holders and secured with one retaining socket-head screw, allowing rapid replacement.

The SCC-15-SS positions the bits along the entire shaft, with no frontal gaps, reducing material into uniform pieces with minimum imperfections or fines, and little to no generation of heat.

The new cutter has a 15 in. (381 mm) throat width that accommodates up to 30 parallelograms with 60 bit inserts. Perforations of the bed screen range from 1/32 to 1-1/2 in. (0.79 to 38 mm) in diameter and up to 3 in. (76 mm) square, allowing the reduction of materials into uniform particles in sizes down to 20-30 mesh.

Material is fed through the top of an adjustable, double-baffled intake chute, or directly into the front of the chute through a hinged door. An independently powered, variable speed pinch roller is offered for horizontal feeding of material. Discharge is via gravity, pneumatic transition or independently powered belt or screw conveyor.

Applications include a diversity of chemical, mineral, foundry and plastics materials.