Editor’s Note: In last month’s Special Report, Packaging World reported on notable applications of packaging materials made from renewable resources. This month’s focus is on how three prominent consumer packaged goods companies make environmentally sustainable packaging part of their corporate philosophies.

In discussing packaging and the environment, some companies deliver flowery prose about their “environmentally friendly” stance. Then there are companies that back up such “greenspeak” by committing to innovative, functional packaging materials and systems that support both environmental and economic health. Three companies making that commitment in their packaging operations are Estée Lauder/Aveda, Hewlett-Packard, and Bacardi Bottling Corp.

For this report, PW spoke with John Delfausse, vice president of package development for New York City-based cosmetics maker Estée Lauder/Aveda; Alison Kent, senior manager, global packaging team, Hewlett-Packard, a Palo Alto, CA, technology solutions provider and maker of computers and printers; and Yousef Zaatar, vice president of packaging at Bacardi Bottling Corp’s beverage plant in Jacksonville, FL.

All three have participated in meetings held by the recently formed Sustainable Packaging Coalition (see packworld.com/go/c093). The nonprofit industry working group’s focus is to leverage cradle-to-cradle packaging concepts that support economic and environmental health.

“The key issue for us at Aveda is to follow cradle-to-cradle concepts,” says Delfausse. “In order to try to do what’s correct from an environmental standpoint, we’ve been concentrating on building recycled content into folding cartons, bottles, jars, closures—really every part of our packages.”

Recent examples, he says, involve the use of “postconsumer PET that we’ve used to repackage our Brilliant styling line in bottles and jars. Last spring we also came out with Light Elements, in PET, which use recycled-content material.” Both are shown in (Photo A).

“Aveda is a division of Estée Lauder and has a strong mission to set an example and take a leadership position for the environment,” Delfausse states. “Our packaging is part of the product in that it has to get somebody to pick it off the shelf and buy it, yet still be cost-effective. Our order of priorities when we design a new package begins with environmental concerns,” he continues. “Cost is second, and design is third. So there’s a real commitment.”

Delfausse estimates that 80% of Aveda’s packaging incorporates anywhere from 55% to 100% post-consumer content. “We have a pretty good corps of suppliers that partner with us in our efforts to do this. They include Alcan and Owens-Illinois for plastic bottles, and CCL for tubes.”

Finding a consistent, clean source for post-consumer resin is a challenge, Delfausse admits, particularly for materials used for closures. “So far there hasn’t been a reliable source of clean polypropylene material, but I think I’ve found one,” he says. He prefers not to identify the supplier.

“In a sustainable coalition,” Delfausse continues, “big beverage companies collect PET bottles in large quantities, but nobody’s really dealing with closures, some of which are colored. Part of the cradle-to-cradle concept is to design a package so you can take it back and reuse it. We’re talking about using closures that are natural in color, so we’re evaluating the possibility of collecting closures from our customers to make it a closed-loop kind of situation. It’s as close to cradle-to-cradle as you can probably get.”

Rewarding solutions

Like Aveda, Hewlett-Packard “strives to find more environmentally conscious ways of developing packaging,” says Alison Kent. “Whenever there’s an opportunity to choose a material that’s better from an environmental perspective, we definitely endeavor to do so. The constant pressure is cost. Finding sustainable packaging solutions that are either cost-neutral or offer a cost advantage has been our challenge.”

In its 2002 white paper on environmental packaging, the company reported that “due to the collective efforts of HP packaging engineers in 2002, the company saved several million dollars and eliminated the waste of more than 400ꯠ tons of natural resources.” Behind the savings were several changes:

•Reusing bulk trays for ink-jet cartridge delivery an average of five times used 2깒 fewer tons of corrugated boxes.

•Shortening the ink-jet cartridge package sleeve reduced paperboard weight, requiring 635ꯠ lb less than previously.

•Eliminating foam cushioning in fax module packaging that would otherwise be landfilled and replacing it with 100% recyclable paper realized both machine retooling costs and material savings. The change also minimized warehouse storage space and the number of trailers required to transport packaging materials, thereby lowering transport costs, fuel use, and fuel emissions.

•Transporting multiple personal computers in large packages for high-volume customers rather than in individual packs was initiated in late ’02. The change was expected to reduce corrugated paper components of packaging desktop computers by 76%; 84% for plastic contents. “Once [these packs are] rolled out worldwide,” said HP in its white paper, “expected savings will exceed 1ꯠ tons in packaging materials.”

•Replacing virgin PP with recycled low-density polyethylene for end caps that protect notebook computers removed 1.5 million lb of PP from the waste stream.

•Standardizing of replacement monitor packaging (Photo B) by using Sealed Air’s Korrvu® suspension packaging allows products of different weights and dimensions to be held in a single box size. HP’s white paper said, “The efficiencies attained have been incredible. Five pallets of Korrvu materials can be used in place of 160 pallets of die-cut foam, and the new material is 100% curbside recyclable.” HP said the innovation provides a 15.5% material cost reduction, 24 fewer semi-trailers to ship packaging materials, and 14 fewer semi-trailers of packaging sent to landfills each year.

Kent says Hewlett-Packard “has a corporate-level program whereby package designers are awarded for designs that are deemed environmentally responsible. People actively compete for those awards. We give out a number of those annually, so the environment is a priority at the company, and it’s something that packaging engineers at HP care a lot about. There’s even greater interest of late in figuring out what we can do to develop environmentally sustainable packaging. We call it responsible packaging, and it’s for products sold to both consumers and business customers.”

Machinery plays a part

Similar to Hewlett-Packard, Bacardi Bottling Corp. in Jacksonville, FL, uses a combination of source reduction and recycled materials as part of its pro-environmental efforts. “Bacardi’s corporate philosophy is to be as ecologically friendly as possible in our day-to-day practice, and it’s strictly emphasized by our upper management,” says Yousef Zaatar.

Zaatar says the company uses “the maximum amount of recycled material” in its corrugated shipping cases “as is allowable by various transportation rules.” That equates to 25%, he says, on inner and outer linerboard and 50% on the medium. That’s less recycled material than Bacardi uses for cases in Europe, “but we couldn’t use as much in the States because it wouldn’t pass burst tests or edge-crush tests,” he contends.

For its glass bottles, Bacardi had used traditional heavyweight bottles produced by a blow-and-blow manufacturing process. For economic and environmental reasons, Bacardi switched to a lighter bottle made via a narrow-neck press-and-blow process (Photo C, p.84). He says that despite those advantages, and the fact that the new lighter-weight NNPB-made bottle is much stronger because it has better glass distribution, the change created challenges.

“After we did that, we found out that our case packing equipment led to some breakage on the line,” Zaatar recalls. “So we began to add a corrugated pad at the bottom of the shipping case to act like a shock absorber and stop the breakage. It was about the size of one of the case panels. Sometimes an additional corrugated pad was also required on top of the bottles in the case.”

While the pads reduced damage, they added material and labor costs. “And they were a waste because they were just thrown away,” says Zaatar. “It didn’t make sense to continue to use them.”

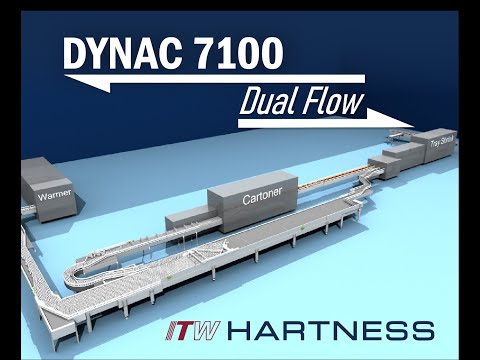

In 2002, he says, the company “made a capital investment in four new Hartness case packers for the line. Like many companies, we look for a two- to three-year payback on equipment purchases, but payback wasn’t the issue for this. It was a long-term investment with a longer payback period. We thought it was more responsible from an environmental standpoint, and in the long term, we believe it will provide a payoff.”

Zaatar says the equipment is doing just that. “We replaced aging case packers, we eliminated breakage on the line, and we no longer need to use the pads. We save money by not buying the pads and save labor costs associated with inserting them.”

Zaatar summarizes the balance between economic and environmental concerns: “I think most people have a conception that being ecologically responsible is more expensive. The opposite is true. You might have some expenses at the beginning, but it’s an investment. If your packaging is ecologically friendly, at the end of the day you can save money.”