On February 8 and 9, the Food and Drug Administration sent a signal on RFID to the pharmaceutical industry that companies clearly received. “I am disappointed at the apparent slowdown in RFID implementation,” stated Acting FDA Commissioner Andrew von Eschenbach at a meeting of the FDA Counterfeit Drug Task Force. Eschenbach asked the task force to figure out what was slowing down drug companies on RFID and to make recommendations to him by May. Based on the comments of the members of the task force, who are all FDA legal, regulatory and enforcement officials, it seems very likely the FDA will develop a mandatory standard requiring pharmaceutical companies to adopt RFID tagging in a phased manner, with the highest-risk drugs going first.

Delay = opportunity lost

At the meeting in Bethesda, MD, where a crowd of 200 packed the ballroom, Eschenbach emphasized: “The longer we delay, the more opportunity is lost.”

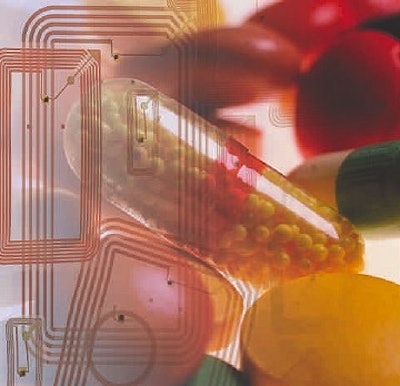

The FDA issued a task force report in February 2004 which said the agency expected widespread adoption of RFID tagging of drugs in 2007 based on what technology suppliers and drug companies were saying at the time. Two years later, Pfizer is the only drug manufacturer to put tags on a drug in commercial distribution, that being Viagra. Some generic drug makers selling to Wal-Mart have also tagged their drugs.

Ron Moser of Wal-Mart, said, “Right now, four suppliers are tagging pharmaceuticals at the package level, on over 20 stock-keeping units. They are all using UHF tags. We have plans to expand item-level tagging beyond those 20 SKUs.” Moser didn’t say so, but others referred to the Wal-Mart participants as marketers of controlled substances.

The FDA is more concerned with the Pfizers of the world. Pfizer was represented at the workshop by Tom McPhillips, vice president, U.S. trade group. In an opening statement, he said, “It would be possible to implement RFID tagging for higher risk products in three to five years. It would take several years beyond that before all drugs could get tags.”

2007 must be possible

On the other hand, Carmen Catizone, executive director of the National Association of Boards of Pharmacy, told FDA officials: “An implementation date of 2007 is possible, and must be possible.”

Several members of the task force referred to that dichotomy: some players in the pharmaceutical industry want the FDA to stick to its 2007 date; others, chiefly the manufacturers and wholesale distributors, say standards, technological and business impediments make a 2007 date impossible. Those differing viewpoints led some FDA officials, in their questions to industry people, to ask about how a phased-in approach might work. Lisa Clowers, senior vice president, industry relations at Healthcare Distribution Management Assn. (HDMA), suggested a phased-in approach where the priority one level would be products highly susceptible to counterfeiting. Priority two would be high-volume, high charge-back products. Priority three would be products used in hospitals. She said her association had no formal position on whether generics should be included in any FDA mandate.

There is no question that the failure of the EPCglobal Health Care and Life Sciences work group to settle on RFID tag and reader frequency standards for pharmaceuticals has been a major roadblock to wider-scale adoption of RFID. Yet it's far from the only one.

Tag gridlock ahead?

“The endless array of competing tag systems will lead to gridlock,” complained John Gray, president of HDMA. EPCglobal did publish a Gen 2-UHF (ultra-high frequency, 915 MHz) air interface protocol for multipurpose use in all industries in December 2004. But that is of use primarily for companies complying with Wal-Mart’s requirements, which is for UHF tags on cartons and pallets. Also, in some instances, it can be used on packages such as those for controlled substances.

However, a number of technology vendors exhibiting products at the workshop explained that the Gen 2 UHF tag has very limited application for drug packaging, a fact proven, perhaps, by Pfizer’s choice of a high-frequency (HF) 13.56 Mhz tag for its Viagra package. Jan Svoboda, business development director, UPM Raflatac, Inc., said, “Generation two may work for a case of hot dogs, but not for a container of pills worth $150.” Svoboda emphasized that HF tags work very well on drug packages right now, and have significant advantages over UHF tags. These include greater security, memory and higher read rates when placed on blister packs or other packages containing metals, and those containing liquids. He acknowledged that HF tags are somewhere between 50% to 100% more expensive than UHF tags, depending on volumes. But he said a focus on cost is shortsighted.

“If you are a distributor in Florida and you can’t authenticate a drug package, you can go to jail,” he said. Substantial expansion of Florida’s current wholesale drug pedigree requirements go into effect in July.

HF the better choice

Ed Gonsalves, business development manager, Philips Electronics, agreed that HF tags are a better choice for drugs right now. “The reason EPCglobal has focused on UHF is Wal-Mart, which took a one-size-fits-all approach to tags,” he stated. “I can understand that from their point of view.” He added that he expects EPCglobal to adopt both UHF and HF standards for drugs.

Pfizer’s McPhillips defended the pace at which EPCglobal is moving. “The EPC global standards' process is not a simple solution,” he said. “There are a number of different people who need to be heard. We will get there sooner rather than later.”

That process will inch forward in late March when EPCglobal holds what Gonsalves referred to as a “bake off” at an Infineon Technologies AG facility in San Jose, CA. Gonsalves said there will be seven or so “use cases,” where applications are set up and different products and frequencies are tested. “Three or four of those will be pharmaceutical industry use cases,” he said.

Even after the standards, data and business practice issues are put to bed, the issue of costs will still have to be quieted. “In our case, it cost $5 million just to tag five Viagra dose package combinations,” McPhillips said.

Moreover, it would have cost Pfizer considerably more had it decided to use the National Drug Code (NDC) number on the EPC HF13.56 MHz tag that backs each Viagra paper label. McPhillips said Pfizer excluded the NDC number because of “readability” concerns. Pfizer uses UHF 915 MHz tags on Viagra cartons and pallets.

McPhillips made it clear that the jury is still out on whether the Viagra RFID investment will pay dividends. “What still has to be determined is the acceptance, performance and utility of the tag in the market,” he noted.