R&D Tool, a retrofitter/integrator/custom builder of packaging systems, was asked recently to upgrade the machine vision inspection system on a labeler operating at a pharmaceutical manufacturer. The labeler operates in a line where pills are bottled and labeled for delivery to hospitals and pharmacies.

According to Bill Maricle, project engineer at R&D Tool, machine vision technology is used on the line not only to ensure that the commodity code pre-printed on the label is correct, but also to ensure that the bar code and date/lot code, which are thermal-transfer-printed on line, are accurate and readable.

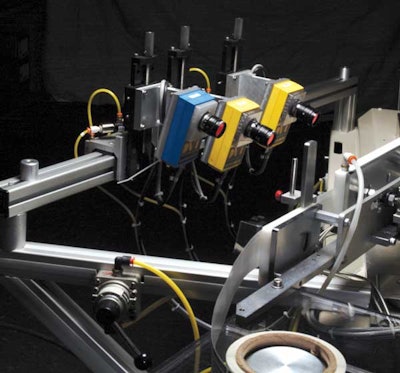

The system Maricle installed deploys three smart cameras from DVT. Responsible for reading date and lot code are IS-5RC cameras, while a DVT 544MR camera checks bar codes. These cameras use image-processing capability in the camera body to make decisions based on what is viewed. The cameras then communicate digital signals to the labeler’s PLC, an Allen-Bradley AB 503 from Rockwell Automation.

Inspection occurs upstream from the peel plate, while labels are still on the release liner. Label infeed is halted momentarily while inspection takes place. If the bar code, lot/date code, or commodity code on any label is deemed incorrect or unreadable, the PLC will halt that label before it reaches the peel plate, and operator assistance will be called for.

A group of LEDs around each camera body provide lighting that makes inspection possible. Labels can vary in size, which means codes to be inspected aren’t always in the same place. So the camera mounts are designed to permit flexible positioning as needed.

The cameras are also tied into an Ethernet network that lets operators at an HMI screen access the inspection system operation, including set-up and programming. Connecting the HMI screen and the smart cameras via Ethernet is a DVT-SL SmartLink communications module. Among the information that shows up on the HMI screen are present image, last failed image, and pass/fail statistics.

Maricle says the new inspection system is a vast improvement over the one it replaces.

“The cameras in the previous system weren’t intelligent,” says Maricle. “They required a separate processor, which made things more complex and which also occupied more space. This is simpler, more robust, and more reliable.”