Consumer packaged goods (CPG) companies in a variety of product segments see value in the practice, primarily as a way to increase their production flexibility and reduce costs, and some product manufacturers plan to increase their reliance on contract packagers for secondary packaging soon.

Saddle Creek Corp. and Contract Packaging magazine conducted the online survey in May 2009 and received 494 responses. They represent the perspectives of both large and small companies that are Contract Packaging subscribers. The data includes analysis of responses for 203 survey-takers who already outsource some or all of their secondary packaging.

Following are top-line results from the survey data. Much more information will be available in the July/August edition of Contract Packaging.

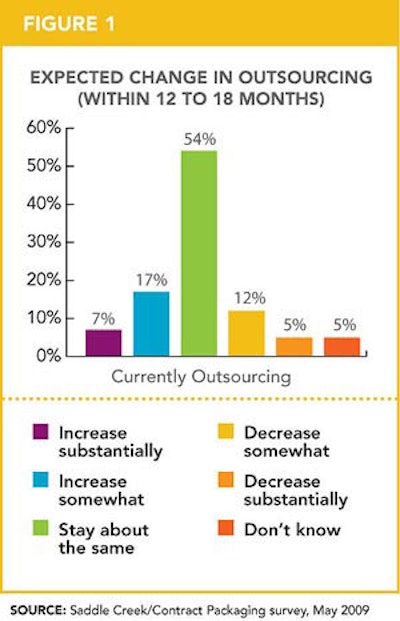

• The survey data supports the adage that your best prospects might be your current customers. As the economy is expected to slowly and moderately begin improving in coming months, CPG companies' reliance on contract packaging services for secondary packaging will increase. Nearly 25% of respondents who outsource at least some of their secondary packaging needs say their reliance on contract packagers will increase "somewhat" or "substantially" during the next 12 to 18 months (see Fig. 1).

• Asked for the top three benefits they derive from outsourcing secondary packaging operations, the respondents most often cited "increased flexibility" (65%), "reduced costs" (62%), and "help in meeting increasing customer demands" (48%) (see Fig. 2).

The results and an analysis of the data by Saddle Creek suggest that many CPG companies view the outsourcing of contract packaging services as a value-added strategic move. Benefits such as increased flexibility and reduced costs seem to be a catalyst for expanding the outsourcing of secondary packaging. Those who indicated plans to increase their use of contract packagers "somewhat" or "substantially" identified "increased flexibility" as a benefit about 76% of the time, and 69% cited "reduced costs" as an advantage.

Achieving flexibility in outsourced secondary packaging operations is important because requirements for such packaging often are seasonal. The ability to find a partner that accommodates demand fluctuations can ease the need to react quickly to changing market requirements.

Hand-in-hand with flexible operations, CPG companies' desire for reduced costs is to be expected in the current economic conditions. Companies are seeking ideas for offsetting or counterbalancing rises in transportation, labor, and energy costs. Product manufacturers that work together with contract packagers can reduce costs in each of these areas.

By reviewing supply chain processes, a contract packager can help to identify and eliminate downtime and reduce the number of touches required in packaging a product, says Robert Pericht, senior vice president of warehouse operations at Saddle Creek.

Saddle Creek Corp. and Contract Packaging magazine conducted the online survey in May 2009 and received 494 responses. They represent the perspectives of both large and small companies that are Contract Packaging subscribers. The data includes analysis of responses for 203 survey-takers who already outsource some or all of their secondary packaging.

Following are top-line results from the survey data. Much more information will be available in the July/August edition of Contract Packaging.

• The survey data supports the adage that your best prospects might be your current customers. As the economy is expected to slowly and moderately begin improving in coming months, CPG companies' reliance on contract packaging services for secondary packaging will increase. Nearly 25% of respondents who outsource at least some of their secondary packaging needs say their reliance on contract packagers will increase "somewhat" or "substantially" during the next 12 to 18 months (see Fig. 1).

• Asked for the top three benefits they derive from outsourcing secondary packaging operations, the respondents most often cited "increased flexibility" (65%), "reduced costs" (62%), and "help in meeting increasing customer demands" (48%) (see Fig. 2).

The results and an analysis of the data by Saddle Creek suggest that many CPG companies view the outsourcing of contract packaging services as a value-added strategic move. Benefits such as increased flexibility and reduced costs seem to be a catalyst for expanding the outsourcing of secondary packaging. Those who indicated plans to increase their use of contract packagers "somewhat" or "substantially" identified "increased flexibility" as a benefit about 76% of the time, and 69% cited "reduced costs" as an advantage.

Achieving flexibility in outsourced secondary packaging operations is important because requirements for such packaging often are seasonal. The ability to find a partner that accommodates demand fluctuations can ease the need to react quickly to changing market requirements.

Hand-in-hand with flexible operations, CPG companies' desire for reduced costs is to be expected in the current economic conditions. Companies are seeking ideas for offsetting or counterbalancing rises in transportation, labor, and energy costs. Product manufacturers that work together with contract packagers can reduce costs in each of these areas.

By reviewing supply chain processes, a contract packager can help to identify and eliminate downtime and reduce the number of touches required in packaging a product, says Robert Pericht, senior vice president of warehouse operations at Saddle Creek.

Companies in this article