Do carbon footprint labels

cause more harm than good?

“kittw04,” Designer

With more environmental concerns today, more companies are preprinting the carbon

footprint of a product on the consumer package to show consumers how much CO2 is emitted. I am just curious whether this might create more environmental impacts due to the package printing and production processes, as the amount of CO2 emitted from the same product would vary depending on how far and by what methods the products are shipped. So the footprint could be different from place to place. This would cause more printing plates for one product, and suppliers may have to split packaging production runs if the products are shipped to various countries because of different carbon footprint figures. Please advise if there are sustainable guidelines on communicating carbon footprints.

See 3 responses to this question: greenerpackage.com/node/2270

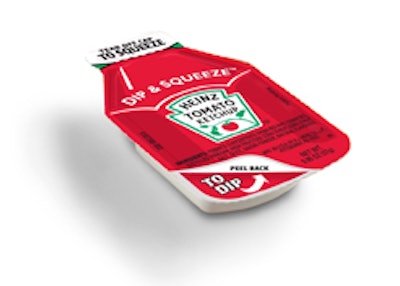

Let’s redesign Heinz ‘dip & squeeze’

for greater eco-effectiveness

Dean Bellefleur, President, D-Idea, Consultant

Just days ago, Heinz unveiled an evolutionary packaging

development catering to the fast food industry: a new “dip &

squeeze” ketchup package. Heinz’ concept of a new “dip & squeeze”

condiment package is brilliant and long overdue in fact. But before we

rid ourselves of the old sachets, let’s consider the functionality of the new package. The dipping concept is a given. It’s actually an intuitive extension of the many single-serve packs that accompany our toast and pancakes today, think butter, jam, and syrups. I would remind our readers however that squeezing residual sauce from a semi-rigid tray is no easy task to perform. From a functionality perspective, it’s inefficient, frustrating, and messy by the time the last drop emerges. How then to redesign the “dip & squeeze” for eco-effectiveness, specifically when it comes to completely emptying the packet?

Add your response to this question: greenerpackage.com/node/2276

Case study requires green inks,

lacquers, and varnishes

Kristiane Wagner, Project Manager Sustainability and Packaging,

Der Grüne Punkt - Duales System Deutschland GmbH, Recycler

For a best-practice case study I am searching for “green” inks, lacquers, and varnishes that meet (to the greatest extent possible) cradle-to-cradle criteria. They should have a proven “green” eco-toxicological profile and be free of toxic heavy metals and organic halogen. The application is the printing of a polypropylene cup for yoghurt and printing of the aluminum lid. Can anyone give me advice on where to start looking?

See 6 responses to this question: greenerpackage.com/node/2267