Blanks Printing and Imaging Co. gives real meaning to the term “quick changeover.” That’s because there’s variety galore in the in-store promotional materials it prints, collates, and ships to retailers around the country. One job may involve millions of pieces while the next involves hundreds. And in the morning the item being collated and shipped might be poster sized while by mid-day it’s the size of a business card.

Employing more than 100 people, BP&I does prepress work, photography, proofing/color management, printing, binding, and fulfillment/shipping. The company serves a broad range of regional, national, and international customers, including high-end promotional agencies.

“One of our keys to growth is that we always assume a customer’s needs are changing,” says fulfillment manager Diane Allison. “We constantly ask about their plans, what they think they’ll need, how their operations are evolving, and then we strive to establish the processes that will advance our customers’ plans.”

Allison credits three new pieces of equipment from Lantech (www.lantech.com), backed up by strong support from Lantech distributor xpedx (www.xpedx.xom), for helping BP&I succeed in keeping up with growth that has practically doubled every year since 2002.

The process that Allison manages, known as “fulfillment,” consists essentially of collating, packaging, and shipping promotional materials that might be used in an in-store promotion campaign at Sears, Penney’s, Wal-Mart, Target, or any number of large retailers around the country. From modest beginnings, fulfillment now occupies about 19ꯠ sq’ in the firm’s Dallas, TX, plant. Much of the department’s work consists of drop-shipping market-specific point-of-purchase material and store signage to support weekly ad supplements mailed to consumers, so turnaround time is nearly “real time.”

“We may receive materials in the morning and ship 1ꯠ collated kits to individual locations that afternoon, combining materials we have produced with those of other suppliers or product samples,” says Allison.

A typical project consists of 1ꯠ to 5ꯠ packages, but the department is equipped to shrink wrap runs from 300 to thousands of packages as needed. The smallest items shrink-wrapped are business-card size; the largest can be 16” W by more than 30” L.

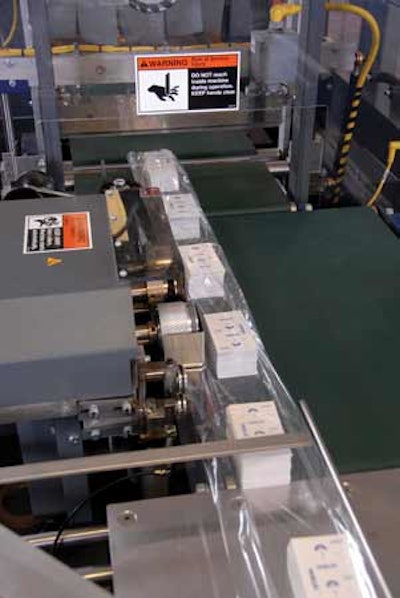

“The key to our strategy is rapid response, so changeover time is critical,” Allison says. “We have to be able to tear down in the middle of one job, switch over to another, then jump back on the original work and finish it. We often collate directly onto the lugged infeed conveyors of the shrink wrappers, which are about 20 ft. long, then do more kitting on the exit side before the conveyors terminate at the case erector. The kitted components are placed in the case, then sealed and labeled by downstream machines.”

The fulfillment department got started in shrink wrapping with a manual L-bar machine borrowed from the company’s bindery department, then moved up by purchasing an automatic L-bar machine. That machine’s 33 packs/min. output proved insufficient for the growing volume, and the quality expectations of one customer were hard to meet using it.

Quality is a must

For most printers, shrink wrapping is needed only for shipping/storage protection, or simple convenience packaging for the customer, Allison explains. Her department, however, also must do retail display-quality packaging, where packaging quality can influence customer perceptions about product quality. “We ship retail packs of as few as 25 sheets of paper that are later unpacked by the customer, inventoried at his end, then pulled and shipped to a retail outlet,” she says. “On these packs, the corners can’t curl or puncture after wrapping. There can be no dog ears of any kind, and the clarity and even the tactile feel of the film are critical. More to the point, this customer inspects every package we ship because any returns from a retailer are costly. Our new equipment facilitates meeting his requirement of 100 percent perfection on received goods. In the long run, it’s cheaper for all of us to adhere to this standard going out our door.”

To meet this requirement and handle additional volume, Allison developed a set of requirements and started research on a second shrink-wrap machine. She attended trade shows and talked to other users and vendors. “I’m not a machinery person, and I had no preferences,” she says. “I just knew my requirements and took them to vendors, working through the selection over six to nine months. We methodically worked through a sound ROI and considered how long a machine would be viable for us if the customer mix and needs changed. We wanted a machine adaptable to small or long items, easy to changeover and maintain, and with output significantly better than the 33 per minute we have with our existing machine. We have non-English speaking people working with us, so we also focused on a machine that would be intuitive to set up.”

She notes that her xpedx rep arranged for several cartons of product to be shipped to Lantech, and after an on-site evaluation of the machine at the factory, Allison ordered an SW-3000 shrink wrapping machine and ST-900 shrink tunnel. The new Lantech system was immediately pressed into service upon arrival.

“The ability to store 16 recipes in the control made it easy to transition into this machine at the outset, when we were still learning our way around,” says Allison. Its side-seal and cross-seal systems have also been maintenance and trouble-free, she adds. “Another manufacturer’s machine we looked at required a fairly skilled maintenance person on hand at all times in the event a jam caused the side seal to fail. That’s a cost we don’t need built in.”

The SW-3000 is a flight-lug machine capable of wrapping up to 75 packs/minute, with on-the-fly film tracking adjustment and side-seal/cross-seal systems that never need cleaning. The flight-lug infeed provides tight control of unstable products and accepts a minimum package of 3”L x 1”W x 1⁄8”H up to a maximum of 40” x 15” x 6”. The adjustment-free rotary side-seal system cuts and seals simultaneously at minimum temperature to avoid melting film on components that could degrade performance or cause a stoppage. The unique system requires setting of only temperature. The seal head can be threaded and checked “cold” for operator convenience. Cross sealing is maintenance-free, too, with a seal bar that cuts and seals with separate surfaces.

Multilingual users

The machine has proven very user-friendly to non-English speaking staffers at BP&I, because the film carriage uses logical settings based on package height/width, with inch-denominated scales on the machine for carriage height, inverting bars, etc. All settings are related to package dimensions in a systematic way. “It’s obvious how it works,” says Allison. “Once you have the package dimensions, you set the conveyor speeds and thread the film and you are pretty much ready to run. This gives us great flexibility with little downtime.” Best of all, the machine typically uses a roll of film two inches narrower than required for the same work on the L-bar. This nets a savings of about $20 per roll of film. “We’re able to use six inch rolls now, where eight inch was our smallest in the past,” says Allison.

Allison is very selective on films, too, and made sure they were tested on all machines she looked at, with her product, during this last purchase cycle. She has settled on Cryovac (www.cryovac.com) Xenith and D940 in a 60-ga thickness for most projects.

The ST-900 convection-heated tunnel has been a factor in the improved quality of the shrink wrapping. Some of the display materials include expensive plastic components easily damaged with heat. “We can tightly control our bag size on the Lantech wrapping machine, and this lets us minimize our heat settings on the tunnel and still get a good looking pack,” Allison explains. “The older L-bar machine and tunnel are more limited in allowing for a perfect package consistently.”

Both shrink machines run hard all day long, and the L-bar machine still has an advantage for Blanks because it allows some “cheating” on product size that’s not possible with the side-seal machine, Allison explains. As for the standard of 100% perfection on the retail packages of paper, notes Allison, “Nothing can ever be 100% the first time because of the variable of the human element that you can’t take out, but the Lantech machine is easily more than 95%, while the L-bar is around 80-85%,” she says.

With high volumes of drop-shipping every day, Blanks has a big appetite for cases. The firm used to dedicate four to six people to erect cases for the kitting line, and give them several hours’ head start to build boxes. Those towers of boxes were a nuisance that could fall like dominoes. They also took up lots of floor space. That has changed with the arrival of a Lantech C-2000 case erector, which survived extensive prepurchase evaluation, including having filled boxes tested by FedEx.

“Our cases ship individually by FedEx ground, so they have to withstand real-world conditions, and they ‘absolutely positively’ have to arrive in good shape—reshipping and re-do’s are out of the question with the schedules our clients work on,” Allison says. “FedEx testing was crucial in our decision, and we found some machines could not make a box that would pass without additional taping prior to shipping, or customization by the corrugated manufacturer. If something’s a little askew on a case, or the center seam overlaps, you can destroy the integrity of your tape and have a bursting situation. xpedx worked with us by allowing us to use a demo machine long enough to test a variety of cases for different projects.”

Big savings

The C-2000 machine is situated on the discharge side of the shrink machines and makes boxes on demand, so packers can efficiently build kits and feed the cases downstream for sealing and labeling. “We had the smaller model on trial but bought the larger machine and have ended up doing more on it than we ever anticipated,” Allison states. “We’ve saved tremendous labor already and even brought more work in from other departments. If the bindery has a shipment of millions of pieces that go 2000 to a box, for example, they can bring the skids up to our conveyors, and we can handle the job much more quickly.” Most of the boxes are 200 to 275-pound-test single-wall corrugated, but Allison says the machine will run double-wall corrugated on certain sizes. “We found the performance specs on this machine pretty conservative,” says Allison. “We’ve also found it to be a very forgiving machine that always makes a square case and never jams. We load 200 blanks in the magazine, and it makes boxes on demand at about 15 per minute.”

The C-2000 works with a range of case blanks from 77⁄8”L x 57⁄8”W x 37⁄8”H to 255⁄8”L x 173⁄4”W x 237⁄8”H. The machine has a number of reliability-enhancing features, such as powered infeed from the magazine, and a hinged pick-up frame that grabs the case on two panels using suction cups. By gripping two panels and squaring the case with the pickup frame, even irregular or damaged case blanks are controlled through opening, then held square and erect for flap closing. Special slots in the major flap folders prevent sideways movement of the case while it is pushed into the exit drive. There, it is gripped on the sides between two belt drives that pull it across the tape head.

The last stop before the FedEx truck is a Lantech Q-300 stretch wrapper with integral scale. The turntable is “sunk” into the floor so the table is flush. This machine, too, was vetted extensively, and it’s paying for itself rapidly through greatly reduced film consumption and labor over previous hand-wrapping methods.

“We used a loaner for some time, and determined that reliability and user friendliness were big advantages with this machine—critical with our workforce,” Allison states. Pallet volume varies from 20 up to about 100 per day, with the fulfillment, bindery, and shipping departments sharing the wrapper.

As BP&I ramps up on its variable data printing, the fulfillment department expects demand to grow.

“We’ll be supporting another product, so changeovers will be even more frequent,” Allison says. “But we’re confident in our system and the support from xpedx. Anyone who had doubts about these machines has seen what an improvement they’ve made in our throughput and efficiency. This machinery has eliminated our weekend work and greatly reduced our overtime. Where people used to expect to work until 10 p.m., they’re now out by 4 or 5. We’ve reduced our material consumption, and built capacity to absorb a growing workload. No one would like to go back to the good old days.”

—Pat Reynolds