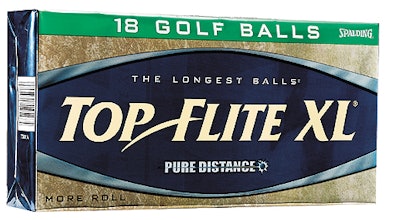

According to Mike McAuliffe, director of marketing for Spalding’s Top Flite brand, the XL and XL-2000 are top sellers, representing some 10% of all golf balls sold in the United States. That’s why they were chosen for the film wrap, which is currently used nationwide to unitize three, four, five, or six three-ball sleeves nationwide.

“We minimize packaging waste, we cut the cost of our packaging materials significantly, and we get a great look,” says McAuliffe. “We’re very pleased with this package.”

The package shown here was recently revised to carry the source-reduction message to consumers. Copy on the top left corner now reads “New Packaging. 54% less waste than previous packaging.”

With a utility patent pending, Spalding is tight-lipped about material specs, nor will the firm identify machinery or materials suppliers. —PR