This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

ACMA’s LRF Platforms allow bottles of different types and sizes to be filled, with various capping systems, making it possible to quickly change format without having to use any tools, with a tool-less and plug-and-play approach.

Two other essential points are filling precision and accuracy, achieved with a net weight system to check each bottle individually. This is a necessary feature to ensure compliance with standards for filling operations and is managed with a degree of accuracy that is unmatched in the market. Additionally, ACMA machines follow a smart filling approach: waste is minimized by reducing the amount of product in the tank using a patented control system – the Virtual Level System (VLS) – and by increasing the speed at which the product is dosed by using a system that constantly measures characteristics such as viscosity and temperature. Maintenance operations are also factored in during the design phase: all our solutions are engineered to maximize efficiency while reducing maintenance costs.

At PACK EXPO, there will be an opportunity to see a recently developed a range of automated and smart distribution and feeding solutions, specifically suited to handle spherical or flat-based chocolate pralines or options for the management of different flat products such as bottles, chocolate pralines or bars and soap bars. There are three variations of ACMA's "smart handling" systems, designed according to the type of product to be processed, how they need to get to the machine, and the production speed of the line being served.

The first one is a smart robotic distribution system with multiple applications within different industries. Designed with space and energy savings in mind, this multi-level smart system handles delicately and precisely chocolate pralines with unusual shapes. The integration of the electrical components directly into the machine, without additional electrical cabinets, and the presence of a single HMI integrated with Coesia OptiMate and PerforMate, make it very compact and easy-to-use.

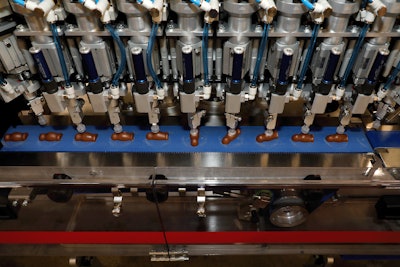

The second one, ACMA Carousel (shown), is a feeding system also for flat-based chocolate pralines, designed to be very compact and with low energy consumption compared to solutions on the market today. It includes a vision system that scans incoming chocolate pralines, detecting and discarding defective ones, and operating in sync with a robot in charge of correct product orientation.

Finally, VL, is the solution designed for spherical chocolate pralines that arrive in the machine from a counterplate. Developed for the ACMA CW 1005 high-speed packaging machine, it is designed for those who have particularly high production requirements but do not want to compromise on quality. Speed is its main strength, an aspect that is combined with high reliability and, again, a compact system size.