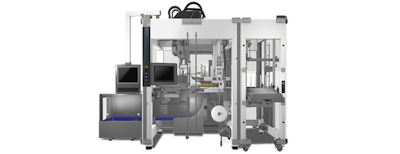

Pester USA debuted at PACK EXPO Las Vegas the PEWO-pack 600, a Delta robot-powered high-speed stretch bundler that introduces several efficiencies, all designed for busy personal care product lines running small multipacks of personal care bottles and related products. The PEWO-pack 600 stretch wrapper system features an integrated Delta robot for fast and efficient pick-and-place of bottles. Using a sleek dual-lane operation, it can wrap small bundles (such as packs of three bottles) at rates of up to 180 bpm.

But it wasn’t only the unit’s high speed that helped the PEWO-pack 600 garner attention from voting attendees and industry media as a Finalist in the Personal Care/Pharma category of the 2023 Technology Excellence Awards at this year’s show.

One of the most interesting aspects of the machine is the sleek stretch bundling technology that wraps products quickly without the need of a shrink tunnel. Pester USA claims this system is 80% percent faster than conventional stretching processes, capable of providing secure and stable stretch wrapped bundles. In terms of materials, the PEWO-pack 600 is engineered to keep up with consumer demand for sustainable packaging, as it can run PE stretch film containing recycled material or film made of recyclable mono material.

This stretch bundler, engineered in Germany by Pester Pac Automation, features a modular pre-assembled sealing unit, allowing for fast assembly times. The design of the stretch bundler eliminates the type of therm units typically needed on other stretch wrapping equipment and handles unconventionally shaped bottles for products including aerosol, heat sensitive, and easily inflammable products.

Designed for maximum machine efficiency in 24/7 operations, the unit also features fast format changeovers and very short changeover times. When compared to conventional shrink wrapping, Pester USA claims the system can help CPG customers save 75% in energy and 50% in material costs while helping them gain 30% more space with the compact unit.

The system also features New Allen Bradley HMI with tangius 4.0 multi touch display.