Multi-Tech Systems International (PACK EXPO Booth S-2338) suggests an economical approach to get more from your existing rotary bottle labelers. They are offering an ELAU servo retrofit for the bottle table, bottle plates and labeling stations to increase reliability, flexibility and throughput.

The keys are programmability, mechanical simplicity and precision. With individually driven servo bottle turning plates, containers remain precisely controlled and both bottle and label size and shape changeovers become simple recipe changes.

Format change times and costs are dramatically reduced, with no need to replace or carry belts, pulleys or cams in inventory. That also means more time making good product, both from faster changeover and faster startup to full production speed with less waste and without ‘tweaking.’

ELAU, Schneider Electric’s packaging specialist (Booth E-6413), is credited with introducing servo control to both rotary labeling and capping, and they offer servo filling solutions as well. Their purpose-built packaging automation systems are found on many new rotary labelers, but for other labelers, retrofit is the only way to achieve servo performance.

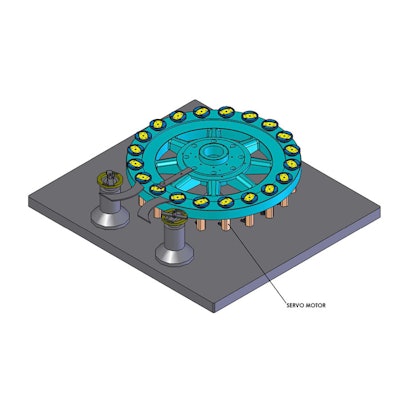

The ELAU implementation uses Intelligent Servo Modules, which greatly reduce wiring and are specifically designed to simplify installation of servos onto rotating machine tables. Instead of a ‘dog house’ mounting many servo drives, the servo modules feature drives integral to the motors. A single, quick-connect cable is all that’s required from the servo module to a distribution module. And there’s only one cable from a common power supply in the electrical cabinet, to a slip ring, to the table-mounted distribution modules.

In addition, the servos allow setting of a torque limit to prevent mechanical damage. To aid preventive maintenance, a warning signal can be preprogrammed to identify increased torque or temperature conditions.

About Multi-Tech Systems

Multi-Tech Systems International Inc. offers a line of hot melt, pressure sensitive and cold glue labelers utilizing European and North American technology to provide extremely accurate label placement. Engineered to last, they are manufactured in North America.

Multi-Tech Systems also has the most extensive rebuild program worldwide for remanufactured Krones labelers and many other Krones labeler components. They provide design, manufacture and supply of change part systems and components for Krones labelers.

For more information, www.multi-techsystems.com

About ELAU packaging solutions

ELAU, Schneider Electric’s packaging specialist, equips over $1 billion worth of packaging machines annually. Currently, over 40,000 purpose-built ELAU packaging automation systems are deployed in machinery worldwide.

Through ELAU, Schneider Electric is the only controls supplier with a dedicated business unit focused exclusively on the automation of packaging machinery.

The market demands packaging operations that are more flexible, efficient and sustainable to fulfill marketing, supply chain and global business strategies. ELAU innovations have enabled a revolution in mechanical, software and hardware modularity to deliver these agile packaging systems.

For more information, visit www.elau.com or email [email protected].