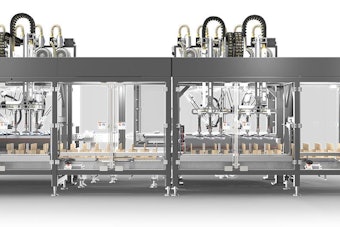

The combiTop® reclosable pour spout is injection molded of polypropylene by J.L. Clark (Rockford, IL). Farmland Dairies has the first straight-line combiTop applicator from Combibloc. All previous models were rotary systems.

The chief advantage of the straight-line version is that a change in package height can be readily accommodated. There's only one application head and it's easily adjusted up or down in minutes. This is not the case with the rotary system, which has 10 application stations and a carousel that must be changed when carton height changes.

Two other advantages come with the in-line system. First, it's capable of keeping up with the fastest Combibloc filling systems. Second, the plastic spouts do not come with adhesive pre-applied. Instead, a Nordson (Duluth, GA) hot melt system applies glue just prior to application. This brings a slight cost savings and reduces the likelihood of spouts sticking together, something that can be troublesome in hot, humid weather.

Operators load the pour spout applicator by dumping the PP fitments into a floor-level hopper. They're elevated to an overhead vibrating bowl, oriented, and then sent down a chute toward the incoming cartons.

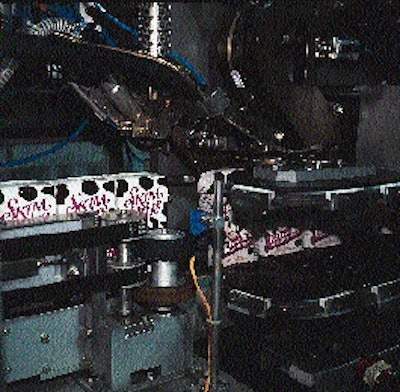

Picking each fitment up from the chute is one of 20 mechanical grippers mounted on a chain that moves continuously like the chain on a bicycle. This chain shares the same drive as the conveyor that holds the cartons, so cartons and fitment-holding grippers are in perfect sync.

Dual sidebelts time the release of individual cartons into the machine with just the right spacing. Each time a carton enters, sensors tell a gripper to pick a fitment from the chute. After rolling the fitment across the glue roller, the gripper meets its designated carton and presses down to marry fitment to carton. The gripper then is ready to go back and repeat the cycle.

It should be noted that the top of the six-layer carton blank, a lamination of polymers, foil, and paperboard, is scored during the converting operation at Combibloc. So when the consumer pushes down on the stay-on tab, it breaks smoothly through the material to provide the desired opening.