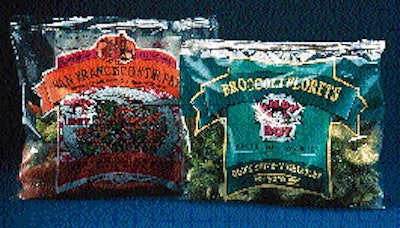

"When the apple is sliced, the carrot shredded or the broccoli cut, a cascading set of physiological and biochemical reactions are initiated which will cause a rapid deterioration of the product." William Romig, EPL Technologies, MAPack '95 Three fresh-cut produce packages each using different ways to retard Romig's "cascading set of physiological and biochemical reactions" are winners of the Flexible Packaging Association's 1995 Top Packaging Awards. (For a look at other FPA winners, see pages 22, 41 and 64.) Though each solution is different, all involve breathable films and passive controlled atmosphere technology. In other words, they extend shelf life by limiting oxygen supply, slowing the live product's respiration rate, and thus retarding spoilage. One of the winning packages is from Met West Agribusiness, a grower/packer in Del Rey, CA (see PW, October '95, p. 2). Its 1-lb portions of Sunmet sliced apples (1) in zippered reclosable bags reached store shelves last September. Refrigerated shelf life is 12 days thanks to the pressure-sensitive Fresh Hold® label developed by Fresh Valley Technology (Salinas, CA) and converted by Avery Dennison (Monrovia, CA). The label is a breathable film membrane that's applied over a precisely cut hole in the bag. It permits the release of carbon dioxide and the entry of oxygen to create an internal atmosphere where the apples can respire and stay fresh. Citric acid, sodium erythorbate and calcium chloride are added to keep the apples from browning. The premade bags, a blend of ethylene vinyl acetate and linear low-density polyethylene, are flexo printed in four colors by Maine Poly (Greene, ME) and supplied on wickets. Met West fills and heat seals them semi-automatically. The apples retail for about $3. Gone but not forgotten Another FPA winner is the package that was marketed by Andy Boy Associates of Parsippany, NJ. They, too, found a way to extend shelf life by means of a breathable film. And even though the produce company went out of business in January, its innovative and award-winning packages are worth examining (see story on Andy Boy Soups, page 58). Shown here are Andy Boy Broccoli Florets and San Francisco Stir Fry (2), just two of the 13 items that made up its line of fresh-cut produce. They were packaged in a 1.18-mil oriented polypropylene, from James River Corp. (Milford, OH), that's microperforated with just the right amount of minute holes. Invisible to the naked eye, they allow the produce to respire at the proper rate. The number of holes is adjusted to meet the varying respiration rates of each variety of product. Depending on the variety, shelf life can be extended for days or weeks. The bags are also anti-fog treated. Salad mixes and other vegetables have been packaged in breathable films tailored to their respiration rates for a couple of years. So why the need for something as exotic-sounding as "microperforation?" Because, says James River, most films used to pack fresh produce are too impermeable for high-respiring products like broccoli, cauliflower, carrots, and cut fruit. Downgauging films to increase permeability is rarely the solution, since it makes machineability problematic. This dilemma was recognized by Sidlaw Packaging (Bristol, England) in the late 1980s, so the firm developed a microperforation process that received two United Kingdom patents. It then created a global trademark, P-Plus(TM), for its technology, applied for overseas patents and began to seek international licensees. In 1993, James River acquired North American rights, and a year later it began producing microperforated films at its San Leandro, CA, plant. As James River's Ted Frey reported in a paper last October, several P-Plus applications have been commercialized, primarily in the oxygen transmission range exceeding 500 cc/100 sq"/24 hrs. Frey also addressed the question of whether the microperforations could become a pathway for microorganisms. "Sidlaw commissioned in 1991 a microbiological study by the Campden Food and Drink Assn. which addressed external contamination," Frey reported. "The Campden report concluded that such ingress would be 'extremely rare.' Fundamentally, contamination caused by poor sanitation prior to packaging presents a far greater risk than the potential for P-Plus holes to create a dangerous microbiological situation." No perfs in PD 900 family While James River went the microperf route for heavy breathers like broccoli and cauliflower, Cryovac (Duncan, SC) pursued a strategy based on resin formulation and process development for its PD 900 family of films. Mann Packing of Salinas, CA, uses the PD 960 variety for its FPA award-winning Rainbow Salad and Broccoli Wokly packages (3). A proprietary coextrusion based on an unnamed polyolefin, the Cryovac film can be as thin as .6 mils. Cryovac claims that represents "up to" a 75% reduction from what it calls "existing films," yet it's still rugged enough to run on high-speed form/fill/seal equipment. Oxygen transmission rates run from a broccoli-pleasing 1갡 cc/sq"/24 hours down to 225 cc/sq"/24 hours, which is more suitable for carrots and onions. It's also available in the form of pre-made bags and with an anti-fog feature. The Mann packages shown here, produced from rollstock on a vertical form/fill/seal machine, were flexo-printed in eight colors by Cryovac. Further information is difficult to come by; a Mann spokesperson says the firm is "not comfortable" talking about the package. Expect to see more of these extended shelf life produce packages in the future. Industry observers predict that fresh-cut produce will constitute 25%, or 40 billion lb, of U.S. produce consumption by the year 2000.