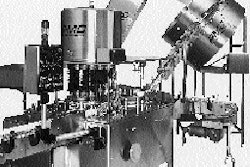

Biocraft Laboratories has regained its competitive edge among contract drug manufacturers through a major reduction in packaging labor costs. Last July, the Fair Lawn, NJ-based company completed installation of shrink bundling systems on 13 lines in three plants. The bundlers from Omega Design (Exton, PA) have been added to lines that package prescription antibiotics, but in a wide variety of dosage forms, from tablets and capsules to powders and liquids. Altogether, the bundling project cost about $900ꯠ. But that's expected to be recouped in a single year through $800ꯠ in labor savings and a $100ꯠ reduction in material costs. "One of the reasons we bought this machine over others was because of the ease of changeover," says Victor DeCandia, corporate industrial engineer. The machine packages bottle sizes ranging from 40 to 950 cc in arrangements ranging from 3 x 1 to 3 x 4. Bottle shapes are varied, with some round and some rectangular; outserts attached to the caps are common. Bottles packed in decorated unit cartons are also bundled on the new machines. The machine's small footprint was also an asset. "On some of our lines, we couldn't fit a machine larger than 10 feet long," says DeCandia. "Other machines we looked at were too large." One model, an SL-18, was installed on all 13 lines, and half were installed at a right angle to fit tight space constraints. The bundlers produce bull's-eye packs at speeds to 25/min across two or three shifts depending on the plant. Prior to installing the new machines, bottles were packed by hand in a paperboard tray, film wrapped and sealed manually on an L-sealer, and pushed through a heat tunnel. "We used to pack manually at a cost of about 8¢ per bundle in materials alone, plus the cost of three workers. The shrink bundlers eliminated the labor and now we're at a cost of less than a penny per bundle," says DeCandia. Materials savings stem from the elimination of the paperboard tray and the machine's ability to handle less expensive film, supplied by Armin (Jersey City, NJ). The 1.5-mil high-density polyethylene film costs 85¢/lb compared to the film that was required previously, which cost $4.80. Bottles convey single-file into the machine's infeed. A sensor verifies whether there are enough containers to complete the desired bundle configuration. Collation is done by a pusher plate that pushes the requisite number of bottles for each row. For a 3 x 4 bundle, for example, the pusher plate will wait for four bottles to accumulate, push them forward, wait for four more, push those forward, and so forth until a 3 x 4 grouping is assembled. That group is then pushed into the film. There are two rolls of film on the machine--one above and one below, heat-sealed together right at the middle. As the bundle is pushed into this film curtain, it creates an "envelope." The seal bar then comes down behind the bundle, closes the envelope, and creates a second seal. Finished bundles are discharged into a small-footprint heat tunnel. After film shrinking, bundles are manually case packed. One challenge to shrink bundling, DeCandia explains, is the light weight of one of Biocraft's products. "We have a very lightweight powder in a bottle that's difficult to bundle. Normally when bottles like this get pushed during collation, they can tumble. But Omega put a feature on the machine (rear moving guides) that can accommodate a really light bottle."