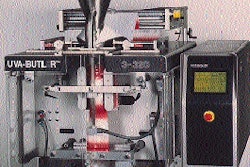

Among the more eye-catching produce packages shown at this year's Food Marketing Institute show May 7-10 was the package developed for Broccoli Time(TM), marketed by Salinas, CA-based Tanimura & Antle. Like other combo kits introduced by produce marketers recently, it offers the consumer a complete meal in convenient, all-in-one packaging. But while T&A's peers have typically opted to put their combo components in a flexible film, Broccoli Time comes in a clear semi-rigid tray thermoformed from rollstock by T&A. "We wanted the package to stand up on display in the refrigerated produce case," says Ken Silvera, general manager of Broccoli Time. The best way to accomplish that is through a semi-rigid package that stands upright more reliably and shows package contents more dramatically than a flexible bag. The billboard effect is so pronounced, the package "practically does our advertising for us," says Silvera. The package's ability to stand upright is a function of its shape. It's about 3" deep at the leading edge and then quickly tapers down to a sidewall at the trailing edge that is less than 1" high. The 3" sidewall at the leading edge becomes the base on which the package stands. One of the four Broccoli Time varieties available is a cream of broccoli soup; the only components inside are fresh broccoli florets, in a breathable film so that they can respire, and soup stock in a pouch made of barrier film. The stock is packaged by an outside firm, but the broccoli is packaged by T&A on a Hayssen (Sheboygan, WI) vertical form/fill/seal system that T&A has used for its ready-to-eat Salad Time salad mixes for several years now. Film specs and supplier are not available from T&A. Broccoli and sauce together have a net weight of about 12 oz. For three nonsoup Broccoli Time varieties-broccoli pasta salad, fettucine alfredo with broccoli, and stir fry broccoli with noodles-inside each tray are the following: broccoli florets in a breathable film, pasta packaged in a barrier film by an outside vendor, and sauce or dressing in a barrier film pouch. Again, all three are already in their primary packages-in clear materials that nicely display color and texture-when it's time to assemble them in the Broccoli Time combo. Waiting for them are two Tiromat form/fill/seal machines from Tetra Laval Convenience Foods (Avon, MA). About eight workers are assigned to each machine, their primary responsibility to load the components into the tray. "Tiromat seemed in the best position to get us a machine in the time frame we were looking at," says Silvera. "They got us started with a demo machine that was available and then we ordered a second, a Power Pack model." Both the entrees and the soup, which has a slightly smaller package than the entrees, can be run on either machine. The newer of the two machines, the Tiromat Power Pack, is a stainless steel system with complete washdown capabilities. PET forming stock Forming stock is a 19-mil polyethylene terephthalate. Forming is done two-up with plug assist and vacuum. Depth of draw is close to 3", which means the material in the corners gets pretty thin. For this reason, says Silvera, a switch to a 22-mil material is currently under consideration. Without sufficient package strength, it's too easy for the package to fall over in its in-store display. After workers load in the necessary components, lidding material is heat-sealed to the formed trays. It, too, is PET, this time 2.5 mils thick. Because it's clear, the produce and pasta show through beautifully. Neither forming stock nor lidding material comes from any single supplier, says Silvera. Net weight of the products in these packages is between 18 and 23 oz. Because the broccoli needs to respire, special heat-seal tooling was designed for T&A so that a series of gaps remain along the flange on three sides of the finished package. Through these gaps comes sufficient oxygen to permit respiration by the broccoli. Throughput on the Tiromat machines is in the range of 30/min. Both trays are made in custom molds, because, says Silvera, "We wanted our package to look different from everyone else's. A premade tray from a custom mold would probably have accomplished much the same thing, but we wanted the flexibility to be able to change the package shape if we see a need to. When you're making your own trays, that's easier to do." One change Silvera says he'd like to make is to somehow divide the tray into sections and use the sections as primary containers for the food items rather than putting pouched or bagged foods in as T&A now does. He admits that he's not sure how to accomplish that, since the broccoli requires breathable film in order to respire while the sauces and pasta need barrier film to stay fresh. Still, it's something he'd like to look into as a means of reducing the amount of packaging currently used. Printed lidstock Another change that's in the works as PW goes to press is a switch from a hand-applied label to a printed lidstock. Silvera estimates the label to be 60% more costly than the printed film. Trays of Broccoli Time are packed into corrugated shippers with ventilation holes in them and then onto the same refrigerated trucks used for T&A's standard produce shipments to distribution centers nationwide. Shelf life, which is 16 days from the date of packaging, is stamped on the clear lidding of the trays as they go through the Tiromat machine. In the supermarket, Broccoli Time is displayed in the salad section, a placement that, says Silvera, underscores its freshness. It retails for $3.99. "Consumers aren't used to seeing ready-to-eat meals in the produce section," says Silvera. "And depending on how the price is displayed, if they see the $3.99 price compared to $1.99 for a packaged salad, they view it as pricey. But if they compared Broccoli Time to Contadina Fresh Pasta, which consists of a 10-oz fettucine with a sauce, for that they pay $5.99 and they don't even get the broccoli." Sales and marketing director Dave Eldridge agrees it's been "a bit of a challenge" getting people used to seeing total-meal concepts among the veggies. Nevertheless, he says the product line, now available in most the country, is doing quite well-well enough that the firm will soon extend the concept with a line of nonbroccoli items. Eldridge isn't saying which vegetable will be featured.