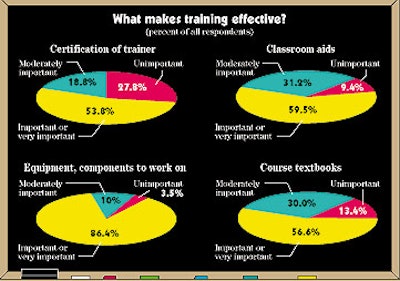

The survey asked participants to rank several components of training programs for their importance in making training effective. Not surprisingly, the most critical component of training on equipment was the availability of the equipment or to have available the appropriate part of a machine system (Chart B). Only 3.5% of respondents thought the same factor was unimportant.

Other factors were more evenly regarded. Each logged “moderately important” responses that ranged from more than one-quarter to nearly a third. And the number of respondents who regarded them as unimportant were more sizable. In fact, trainer certification and course manuals and textbooks were deemed as important/very important by just slightly more than half of the participants.

Survey respondents were often vocal about these factors. “More training documentation on troubleshooting problems,” was sought by a respondent with a national maker of personal care products. A representative of a major national maker of cleaning products asked for “quick-reference troubleshooting guides, along with good documentation for classroom-type training.” This was echoed by a participant from a regional food company. She sought “better documentation to accompany machinery,” but also wanted “better after-sale support by phone.”

The representative from an industrial products maker simply wanted “manuals written in English, rather than machine translations from a foreign language like Japanese.”

As part of the documentation, “OEMs should develop a Training Outline for new operators,” said a medical products company participant. “This could be a section in the Operation Manual,” he suggested. A representative of a national juice processor asked for more “maintenance training and instructions, especially procedures for changing out specific machinery components.”

A furniture maker’s representative asked for “more printed reference material.” The participant from a veterinary products company was more critical. “Most machine manuals are terrible. They list multiple base machines, most options available (except the one or two on your machine) and parts lists and diagrams are often wrong. The manual,” he said, “should be the base on which to build training, not a slap-together afterthought.”

Meanwhile, some respondents were concerned with the trainer. The representative of a maker of medical products had a simple request. “Make sure the trainer speaks English and knows the machinery inside and out.” A participant from a major pasta maker asked that “OEMs put more effort into developing technicians to be better trainers.”

See the main story that goes with this sidebar: Packagers eager for more training