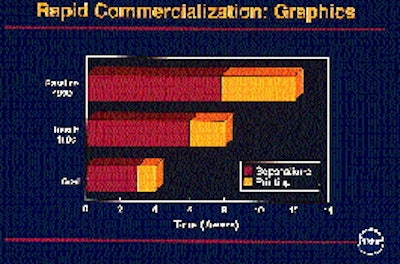

Two parallel trends in packaging are converging at Pillsbury, the Minneapolis-based unit of Grand Metropolitan of the U.K. Packaging professionals at the food company have taken a hit, so much of their in-house work has been shifted to suppliers. At the same time, the company is working hard with its suppliers to wring as much time as possible from the process that begins with product concept and ends with a new commercial product. Today, some 20% of company sales and profits are derived from new products. In fact, consumers are barraged with them. So reports Michael Kentala, Pillsbury packaging sourcing leader. He and Lori Hamilton-Brown, manager of flexible film sourcing, spoke at Flex Pak '97, a spring conference sponsored by Schotland Business Research (Skillman, NJ). For Pillsbury, the importance of new products to revenue is reinforced by the fact the company introduced 180 new product offerings last year. However, Kentala says, the company that brings new products into the marketplace quickest usually enjoys greater sales and profits than those companies that create "me too" products. This, he says, results in a quicker payback on capital costs and development expenses. That's why it's important to beat the competititon into the marketplace and to take advantage of fickle consumer tastes. This has created a stronger focus on shortening product/package development cycles. Doing so, Kentala says, can lead to quicker new product introductions. Kentala told the Flex Pak audience how, at a recent BrandWeek conference, he was reminded that "at the core of every successful brand is a visual image that expresses the brand's identity." That visual image springs from a product's packaging, says Kentala, which is one of the few ways to reach 100% of a manufacturer's customers. As he put it, "Packaging has power with consumers." Today, Kentala says, consumers have to choose from some 30ꯠ products on average in a store and make two-thirds of their decisions while in the store. On most shopping trips, a consumer plans to buy 10 items, but actually purchases 19-all in 22 minutes. "Packaging is clearly the difference, not only to stimulate buying more products, but to get them to buy our products," he stresses. Suppliers' bigger role In sourcing, Pillsbury relies on suppliers more than ever before. They help Pillsbury define product concepts, provide materials, packages, testing and financial analysis. They provide materials and service during scale-up and beyond. "In package development, we push a lot more back on to suppliers now," Kentala says. "Today, Pillsbury is operating with one-third fewer packaging professionals than we had in 1985, and we're a much bigger company. Now we're project managers." To reduce the time from product concept to the marketplace, packaging suppliers must be involved from the beginning, Kentala says. That way they can help define the package design criteria while the product is still in the conceptual stage. It's a matter of both the supplier and Pillsbury identifying the "levers that make the packaging work," he says. He cited how product microwavability or portion sizes could be determined at the early stage. Suppliers can help by providing working prototypes for consumer tests at reasonable costs. As well, suppliers can help by conducting tests on materials, products and the product/package interaction to check for compatibility. "It used to be we tested our products alone with consumers, but that's not true any longer," Kentala says. Now products and packages are tested simultaneously. Later, suppliers can offer expertise as Pillsbury works to scale up its production and packaging operations. "Often they can help our capability to achieve packaging line rates of production even though we're operating off-line," Kentala says. "All of this aids us in achieving rapid commercialization." To make shorter development times a reality, supplier selection is critical, Kentala says, and the Pillsbury approach is called "strategic sourcing." What's strategic sourcing? In comparing strategic sourcing vs. a traditional purchasing approach, Hamilton-Brown says the new strategy uses a multi-disciplinary approach instead of a functional orientation. As well, it brings a clear focus on business requirements, not just on markets and suppliers. But the most obvious difference, she says, is that it's a systematic process to capture and implement opportunities. The normal purchasing process neither looks for opportunities nor does it initiate projects. In a traditional purchasing approach, the supplier is kept at arm's length, the goals are functional and the measurements are activity-based. The result is a single purchase. Strategic sourcing, on the other hand, considers suppliers as business partners, working with them even on upfront research. The two partners share common goals and measurements, focusing on what each company and the consumer requires. Most important, Hamilton-Brown says, is that the result is not just a purchase at the best price, but a purchase of the best material that meets all of the goals. Because of the integration of research by both parties and a shared understanding of the complete process and the consumer requirement, the specification for the material is developed jointly by the packager and the supplier. Hamilton-Brown went on to describe what Pillsbury calls Sourcing Strategy 2000. It's made up of five points: leveraging volume with growth, aligning the supplier base with leaders in the business, leveraging supplier capabilities and competence, optimizing material flow, and sourcing with a global vision in mind. She points out that 50% of Pillsbury's growth is now overseas. For the purposes of Flex Pak '97, Hamilton-Brown elaborated on what this means for the company's flexible packaging purchasing. At the top of the list was working with packaging leaders. She explained that "leaders" doesn't always translate into just the big companies. Leaders can also mean the innovators. Capital expenditures will track closely with new technologies. One of the major focal points in these technologies will be in graphics capabilities. Finally, the strategy must include manufacturing efficiency. Total cost is important, so this means value, speed and productivity. She then described what the company means by optimizing raw materials. With strategic sourcing, the development of the package spec in research & development is measured by value. That's obtained by adding quality and service and dividing it by cost. Next Pillsbury looks at suppliers by considering speed. This, she says, is made up of reduced leadtimes and by manufacturing flexibility. Finally, Pillsbury looks at materials replenishment and use. For this, Pillsbury evaluates by measuring productivity, or the efficiency of replenishment and the use of the materials. Rapid commercialization Just one step in speeding up commercialization of a package is to cut the time needed to produce package graphics, Hamilton-Brown points out. From 1990 to last year, for example, the company has cut the time needed for graphics by one-third, from 12 to eight weeks for separations and printing. However, the goal now is to cut this time from eight to four weeks, allowing three weeks for separations and just one week for printing. Already, she says supplier leadtimes have been cut in half, from 60 to 30 days, since 1990. However, as with graphics, the Pillsbury goal is another 50% cut to 15 days. Against a backdrop of a computer, she explained that these goals can be realized due to improved communications tools. She cited electronic data interchange, bar codes, schedule sharing, direct computer access, transportation synergies and even e-mail. All of these tools can result in minimizing the product development cycle. Hamilton-Brown was asked about whether Pillsbury preferred single-source partnerships or multiple vendors. While acknowledging that certain vendors had key strengths, she said that Pillsbury now focused on developing multiple partnerships rather than single sourcing. She also noted that Pillsbury does work directly with flexible film manufacturers in developing new materials, rather than working with them only through converters. The consolidation of packaging companies does affect Pillsbury's supply strategy, Hamilton-Brown admitted, saying that broader capabilities can make larger companies more attractive. However, it's still important "that we don't lose the innovations that smaller companies can bring." When asked about the considerations a supplier must meet to be qualified as a Pillsbury vendor, the speaker said there were three main concerns: Pillsbury's experience with a supplier, the supplier's financial condition and the innovations the supplier can provide. Packaging development, Kentala added, is market and consumer driven. That's why the company is doing more research on packages. In Pillsbury's new integrated sourcing teams, a packaging professional literally "sells" a packaging material to the team before a purchasing decision is reached by the complete team that includes marketing, production, quality control, packaging and purchasing personnel. And just because the company has established an alliance with one vendor, the company won't close the door to evaluating other possibilities. Ideas, she points out, come from all sources, even from Pillsbury's manufacturing people. In summing up the Pillsbury session, Ed Davies, the moderator, said that the purchasing mantra may be changing. It used to be "faster, better, cheaper." Now, he said, it sounds like "faster, faster, faster."