This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

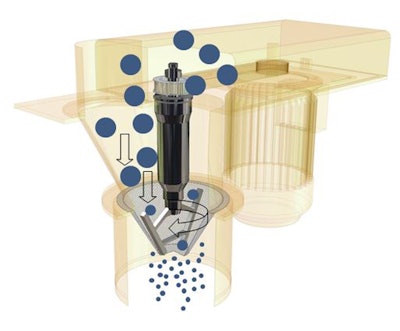

Developed for milling materials from 150 μm to 12 mm, Gericke cone mills allow the gap between the rotor and screen to be adjusted, based on the targeted particle size and shape, from outside the machine. The cone mills move dry, moist, fatty, sticky, and heat-sensitive materials over a conical, serrated screen, passing on-spec particles through to discharge and recirculating larger particles back to the cutting chamber for further size reduction. Available in three standard models, the mills include a quick-release access to the cutting chamber and rotor assembly, food quality seals, and a variety of screen sizes, hole shapes, and patterns.

Make plans to visit PACK EXPO International to see the latest technologies for food processing and packaging machinery and materials.