When most co-packers think of ERP, they envision disruption: months of chaos, blown budgets, frustrated operators, and teams stuck reconciling spreadsheets instead of running production. But at Stutz Packing, things went differently.

By doing a phased rollout strategy and focusing on operator adoption, Power Central helped Stutz transform the ERP deployment from a dreaded project into a seamless part of daily life — even boosting production efficiency along the way.

This is the story of how they did it — and why it worked.

Company Background:

Founded in 2013 in Indio, California, Stutz Packing Company has grown from a family venture into a trusted partner for businesses nationwide. They specialize in dry fruits, nuts, and primary packaging, with a customer base ranging from retailers to national brands. Their high-speed lines and rigorous process compliance make them one of the most efficient co-packers in the industry.

Before implementing ERP, Stutz operated with an impressive home-grown WMS built in Microsoft Access, which handled lot and pallet tracking and served their early operational needs well. Accounting, however, was managed separately in QuickBooks, requiring double entry of transactions. As the business scaled, the cracks began to show—particularly around financial visibility, mobile traceability, and the growing inefficiencies of disconnected systems.

The Challenge:

Despite their strong operational foundation, Stutz Packing faced key limitations that started to bottleneck growth:

· No integrated financials meant no real-time cost-per-pack visibility.

· No mobile barcoding led to time-consuming manual data entry, increasing the risk of errors and slowing down processes.

· Putting together true margin analysis — from transportation bids vs. actuals to production, sales, and purchasing — required days of spreadsheet work, often cross-referencing QuickBooks, WMS and other Excel data.

As Stutz scaled, it reached the limits of its WMS system. They needed a full ERP like Power Central to gain the financial insights and operational agility required for continued growth — but without disrupting the floor.

The Costly Lesson:

Before working with Power Central, Stutz tried to implement ERP with a different vendor in the traditional way ERP consultants deployed ERPs in the past. The experience was frustrating and expensive:

· They invested 300% of their original budget trying to get the system live.

· Even after a year of effort and paying consultants hourly, the ERP never became usable for the operators on the floor.

· The system was too rigid, too disconnected from real-world production — and it left Stutz with no clear path forward.

“The way the previous vendor implemented the ERP, our team was spending three times as long entering production orders as they did with our existing Access-based WMS. No mobile apps. No real-time data. No visibility into labor or line efficiency. Just more work — and no value,” says Fred Partlo, CEO of Stutz Packing.

It was a painful lesson that the wrong ERP approach can drain resources and morale without delivering value. That’s why this time, Stutz knew they needed a different partner — and a different approach.

The Approach:

When Stutz decided to implement ERP, they knew they needed a deployment model that matched their culture and operational excellence — not just another “go-live” checklist.

Instead of training a handful of managers for a week or two and then hoping everything would trickle down to the floor, Power Central emphasized one process and one SKU at a time — ensuring that every operator, supervisor, and manager gained real-world experience and confidence in the system before moving on.

Power Central’s ERP offering came out of the box with Mobile-Barcode apps tightly integrated with Business Central ERP

Power Central’s approach was different:

What made this approach even more effective was that Power Central came ready with:

✅ A pre-configured Microsoft Dynamics 365 Business Central ERP tailored to the food packaging industry — including package and lot tracking, production and batch processing, and ability to track customer contracts end-to-end.

✅ Mobile barcode apps tailored to Stutz’s real workflows, making tasks like shop floor receiving, production, inventory movements, and shipping intuitive and error-resistant.

And Power Central didn’t stop there.

They walked the floor with operators, watched over their shoulders as they used the apps, and adapted the tools based on real end-user feedback — not just formal requirements. This continuous improvement built trust from the ground up, ensuring the system felt like their tool, not an imposed solution.

Here’s how that looked in practice:

✅ May–June 2024: Started with just 2–3 flagship SKUs, focusing on purchasing — no pressure to learn everything at once, just get one area right. Within six weeks, every Purchase Order and Warehouse Receipt was being channeled through the new system. The labels automatically generated from the ERP began replacing the manually printed placards and receiving paperwork.

✅ July–August: Expanded into production workflows, giving the team time to get comfortable with mobile barcode apps and real-time process visibility.

Focusing on one process at a time gave the operators to train on every day tasks as well as exception handling without getting overwhelmed.

✅ October–November: Layered on shipping and outbound processes. By mid-to-late November, 100% of all operations, including Procurement, Production, and Shipping, were being channeled through the new system. Every operator — from accounting to operations to shop floor staff — was fully comfortable with the system and trained not only on day-to-day workflows but also on exception handling.

✅ December 9, 2024: “Went live” — but the floor staff didn’t even notice. ERP was already a natural part of how they worked.

This phased, operator-driven approach — combined with ready-to-deploy tools that evolved with user feedback — ensured that adoption was organic, not forced. Every team member saw the benefits before the ERP became the system of record. Plus, with milestone-driven payments rather than hourly billing, Power Central’s incentives were fully aligned with Stutz’s success — no surprises, just results.

Looking ahead with AI Powered Actionable Intelligence

With reliable transactional data now flowing through the ERP, Stutz was able to unlock a new layer of real-time decision-making.

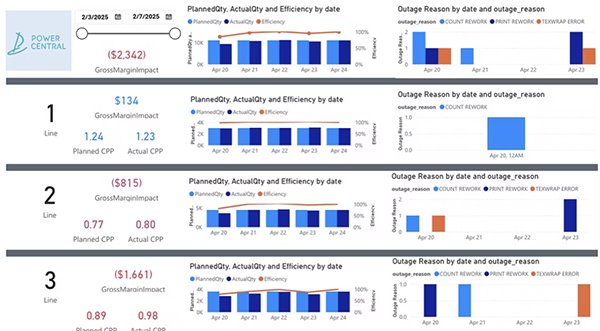

February 4, 2025: Stutz began using Power Central’s pre-built Power BI dashboards to gain real-time visibility into margins. Several reports were customized to reflect the unique way Stutz handles freight charges — giving the leadership team instant clarity into true gross margins across customers and SKUs.

Power Central had Pre-built Power BI Dashboards to show where the margins were eroding due to machine downtimes and reworks in real time

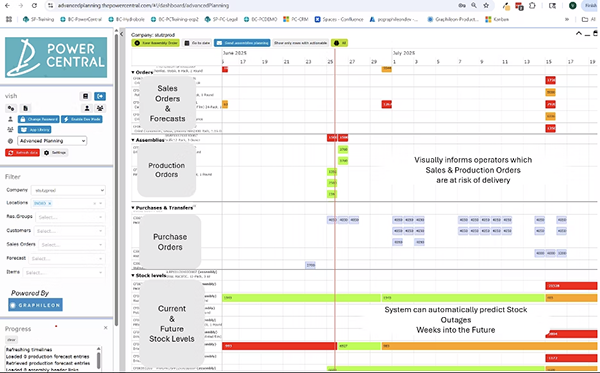

March 1, 2025: Power Central then deployed an AI-powered Advanced Planning tool, enabling its Production and Procurement teams to schedule production and purchases with foresight. The software layers sales forecasts, purchase plans, and real-time inventory tracking using a graph-based engine — surfacing potential inventory or scheduling issues weeks or months ahead of time through intuitive visualizations.

Power Central’s AI Powered Advanced Scheduler visually shows Production and Sales Delivery risks weeks into the future

Why It Worked:

👉 Built on a Strong Foundation:

Stutz’s home-grown WMS gave them a disciplined operational backbone. They didn’t need to reinvent processes — they needed financial integration.

👉 A Partner Willing to Take Risks with Stutz:

Power Central aligned incentives by tying payments to milestones, reducing capital risk and rebuilding trust after their previous ERP struggles.

👉 One SKU, One Process at a Time:

Operators adopted the system without being overwhelmed, gaining confidence at each step.

👉 No “Big Bang Go-Live” Mentality:

By the time the final phase was deployed, ERP was already part of the daily workflow.

Results:

· Improved inventory accuracy

· Real-time cost-per-pack visibility

· Reduced production downtime

· Higher operator satisfaction

Fred Partlo, CEO of Stutz Packing, summed it up: “Power Central demonstrated a truly collaborative approach throughout our ERP implementation. They actively solicited and integrated insights from all departments during decision-making, creating an environment where feedback was welcomed and valued, which was a key factor in the project's success. This cooperative spirit, coupled with Power Centrals' training strategy – which effectively catered to management and end-user needs – was instrumental in achieving a successful go-live.”

Takeaway:

ERP doesn’t have to be disruptive. By rolling it out one SKU, one process at a time, Stutz Packing turned a failed ERP experience into a growth driver — on top of an already strong operational foundation.

For other co-packers looking to scale without chaos, Stutz’s journey is proof there’s a better way.

About Power Central:

Power Central helps food and personal care manufacturers scale profitably with a hands-on, operator-first ERP built on Microsoft Dynamics 365. With mobile apps, real-time costing, and a phased rollout approach, Power Central delivers full-stack visibility without the disruption.

Learn more at www.thepowercentral.com