This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

Using the Bosch high-speed bar packaging system, confectionery manufacturers are now able to boost their production and meet increasing demand for bars. The primary packaging technology on display at the show comprises the Sigpack DCI distribution station and the Sigpack HRM horizontal flow wrapping machine with high performance splicer. These machines can be integrated with the Sigpack TTM toploader to create a system designed specifically for the primary and secondary packaging of bars and bar-shaped products. Using the company’s decades of experience in packaging technology, Bosch has developed a bar line that addresses the key requirements of bar producers, from speed and hygiene to ease of operation, flexibility and efficiency. “With the new bar packaging line, Bosch has designed a system with the operator in mind that reduces necessary manual operation and allows for high speeds of up to 1,500 bars per minute,” said Philipp Schenker, product manager at Bosch.

Seamless design for speedy production

The Bosch high-speed bar packaging line is designed as a single, seamless system rather than a chain of machines. To achieve a reliable and optimized production flow, the speeds of all components in the line are balanced to eliminate bottlenecks and minimize downtime. The Sigpack bar line was upgraded and is now capable of an overall output of more than 1,500 bars per minute and up to 150 cartons per minute. The bar packaging system, including distribution station, accumulator, flow wrapper, toploader as well as all interfaces, are part of one single design. This integrated design makes operation of the entire line as simple as operating a single machine and reduces the risk of operator error, which can cause lengthy and costly production stoppage.

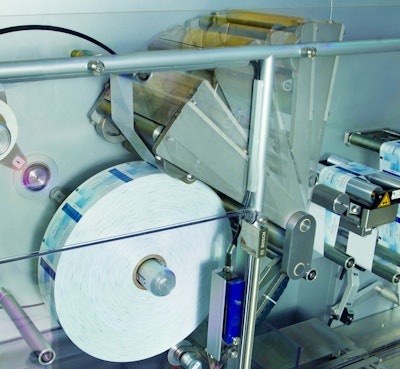

Automated precision splicing

Standardized parts and components, as well as high visibility and accessibility, simplify cleaning and maintenance of the line. Automated precision splicing at high speeds of up to 150 meters per minute means operators simply have to place new reels into the splicer – everything else is done by the machine, reducing the risk of human error. The accuracy of the splicing process reduces waste and material costs. Cleaning and format changeover times are reduced to just minutes through optimal accessibility, tool-less changeover and innovative changeover strategies.