A continuing theme for consumer packaged goods companies seeking new packaging equipment today is their need for machine flexibility to handle a variety of package sizes and configurations with minimal changeover. But nowhere is this more crucial than in co-packing and repacking facilities, where product selections and packaging formats can vary wildly. Number1 Logistics Group is a prime example. With more than 60 clients in the grocery industry, the Parma, Italy-based provider of integrated logistics, co-packing, and repacking services regularly deals with packaging formats as varied as cartons, flow-wraps, glass jars, cans, and more.

One of Number1’s services, repacking, involves the assembly, filling, and stacking of box pallets and retail displays for supermarkets and large-scale retailers to introduce new products or for promotions. Until January 2016, Number1 was building, filling, and stacking the displays all by hand.

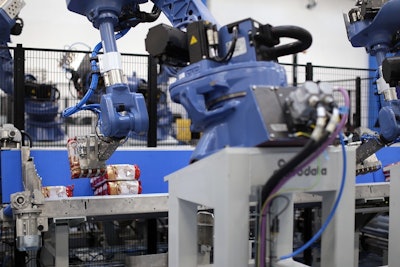

In January 2015, Number1 began working with system integrator Siscodata to automate the entire line with robotics.

Now, in the display building area, box pallets and tray displays are erected using a Comau NJ40 six-axis robot, which begins by automatically picking the display blank from a silo. The robot then breaks and bends the sheet in the middle and glues the display onto wooden pallets with a hot melt system, and, if necessary, inserts a sheet of cardboard inside the display. During the building of the tray, the side flaps are left open to allow for insertion of products during the pick-and-place phase.

Next, in the pick-and-place area, four Comau NS12 six-axis robots on two lines automatically fill the displays with products in a range of packaging formats. The system can fill box pallets and tray displays up to 600 x 400 mm and incorporates a buffer station that inserts cardboard separators between layers, if required.

According to Siscodata President Roberto Brambilla, the NS12 robots can easily handle many different products thanks to a special gripper tool that can automatically be changed based on the product. He adds that the robots include features such as IP67 wrist protection, a fifth-generation Comau C5G controller, and Comau’s portable TP5 teach pendant.

After filling, in the case of the tray displays, the robots close the top of the tray, and the side flaps are glued using a hot melt system from Robatech.

The robot then places the trays onto a wooden mini pallet that comes from the display building area. In the case of the box pallets, they are already equipped with a mini pallet or cardboard frame, added during the display building process; consequently, they do not need further processing inside the stacking area.

With the addition of the five robotic arms, the line is now able to consistently build 40 displays/hr, a level of productivity and efficiency formerly unattainable with manual processes, Number1 says. The system has also made it possible to reallocate operators to other functions that are safer and less physically demanding, including loading products onto the conveyor belts for delivery to the pick-and-place area, monitoring the progression of the line, and taking prompt action in case of problems.