PW: What’s out there in the way of packaging machinery developments?

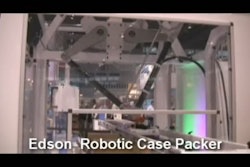

Baker: I see a lot of exciting options out there, partly because some of our equipment is getting fairly dated. One example is in case packers. Ours are semi-automatic, so they don’t really have the kind of diagnostics built in that I’d like to see more of. As things stand now, it’s up to the operators and maintenance technicians to do all the troubleshooting. They have to identify what’s going on with the machine. And the equipment isn’t very flexible, either.

PW: One thing we heard frequently at the just-completed Pack Expo International was that packaging machinery is getting more compact. Does that ring true for you?

Baker: Yes it does. Recent developments in automation technology make it possible to build packaging equipment that will do the same job as the machines we now have but with a smaller footprint and with fewer mechanical parts involved. I also see in new machinery an opportunity to interface with other parts of the packaging line much more effectively than we can now. Take the data stored in the PLC, for example. It’s there to be used, for diagnostics usually. These are the kinds of things we’d like to take advantage of.

PW: The other major theme we heard at Pack Expo revolved around flexibility.

Baker: That’s another thing we’ll be addressing soon. We have 12- or 24-count cases, and going from one to another is a completely manual process. A push-button approach would be more to my liking. And it’s not just in case packing that we see opportunities for upgrades. From unscrambling to filling to shrink wrap, there are a lot of good equipment developments out there.