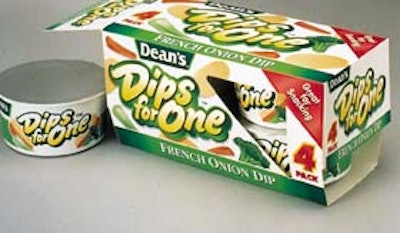

Early next month, Dean Foods’ Dean Dip and Dressing Co. will roll out Dean’s Dips-For-One™ four-packs of 2 3/4-oz single-serve cups of chip dip sold in the dairy case. Thermoformed polypropylene cups and foil-laminated lidstock come from Winpak Portion Packaging (Bristol, PA). Winpak offset-prints cups in six colors and flexo-prints lids in one color. Thicknesses were not divulged for cups or lidding.

A 14-pt SBS sleeve holds the cups in a two-on-two configuration. Rock-Tenn (Norcross, GA) offset-prints the sleeve in six colors. Die cuts permit consumers to see the cups inside.

“We have a strong base dip business in 16-ounce containers, but the four-pack, single-serve package is brand new for Dean’s,” says Phil Dolci, director of marketing for the Dean Dip and Dressing Co. “The pack fits well with consumer trends, and the dip can be eaten anytime, anywhere.”

Rosemont, IL-based Dean Foods says Dips-For-One creates a new segment in the refrigerated dip category. A company press release notes, “no other individually packaged, single-serve refrigerated dip exists in the market at this time.” Dolci says the four Dean’s varieties have a 115-day shelf life from date of manufacture. He also tells Packaging World that the same package configuration will be used for three Marie’s-brand vegetable dips (inset below). “They’ll have a 105-day shelf life,” he explains. “And they’ll be sold refrigerated in the produce section.”

The Marie’s Dips-For-One offerings, which include different ingredients, will retail for $2.99, $1 per pack more than the four Dean’s-brand varieties. The Dean’s four-packs will be sold at the same price as Dean’s 16-oz cup.

Dean’s invested in a new in-line cup filler/sealer from Winpak at its Rockford, IL, plant. After sealing, cups are shipped to contract packager Peacock Engineering (Itasca, IL) for cartoning and case packing. “We do that because there would be a major up-front equipment cost for sleeving and casing equipment for the new product,” Dolci admits. Right now, he says, “It’s far more [efficient] to outsource [those tasks].”

When asked to justify the cost for the new pack’s research, material and equipment, Dolci says, “There’s a large volume opportunity for this type of product. We have internal sales [forecast] numbers, but we just can’t share them.”

One thing the company isn’t shy about is touting its product/package innovation. “Across all of our divisions we are researching ways to better suit the lifestyles of our consumers,” says Luis Nieto, the company’s vice president of business strategy. “In dairy with Milk Chugs, in our pickle division with Picklevator and now in dips and dressings with Dips-For-One.” (JB)