If the Food and Drug Administration requires expanded use of bar codes on drug packaging, pharmaceutical manufacturers will frantically start looking for real estate, but not of the terra firma variety. Both prescription and OTC (over the counter) drug packaging executives will have to find room on individual blister-packed capsules and single-use items, such as syringes, for a new, expanded bar code.

Bruce Cohen, a packaging technology executive at GlaxoSmithKline, Philadelphia, PA, estimates that some of the blister-pack sizes will have to increase by approximately 40%. That in turn could compromise blister packaging line output by as much as 60%. To compensate, a company would have to add several additional blister lines if it wanted to stay at current output.

The FDA previewed a fuzzy look of what a bar-coding requirement might look like on December 3, 2001. But numerous details were missing. An FDA mandate probably won’t be finalized until the end of the year, if then.

Hospital deaths

It was a National Academy of Sciences report that estimated that between 44ꯠ and 98ꯠ people are killed each year in hospitals because of medical errors.

A major cause of deaths was patients receiving the wrong medication or the wrong dosage. The former typically happens when similar-sounding drugs are confused, for example, when Zantac is inadvertently substituted for Zyrtec. The NAS report suggested bar coding of pharmaceuticals as a remedy.

In response to that report, the FDA chartered the National Coordinating Council for Medication Error Reporting and Prevention (NCCM ERP). Representatives from numerous trade groups, including the pharmaceutical manufacturers group, PhRMA, are members of the council.

On June 27, 2001, the NCCMERP recommended that pharmaceuticals used in hospitals have bar codes containing the National Drug Code (NDC), the expiration date, and the lot number. It also backed bar coding “down to the unit-of-use package.”

Which symbology?

Tom McGinnis, director of pharmacy affairs in the FDA’s office of policy, says that the bar-coding remedy has caught the personal interest of Health and Human Services Secretary Tommy Thompson. McGinnis says that the FDA will be looking at the NCCMERP recommendations, but will be sensitive to what any bar-coding mandate will cost drug manufacturers.

GSK’s Cohen was one of those representing PhRMA at a NCCMERP presentation on presumed bar-coding costs. He explains that at least 90% of GSK’s packages already have bar codes, although they contain only the NDC number. If FDA follows a NCCMERP recommendation to include the lot number and expiration date in the bar code, changes may be in order. GSK and other drug companies may have to change to a code 128 format if they are going to add the RSS (reduced space symbology) compact code for lot number and expiration date.

The RSS code is being developed by the Uniform Code Council. It is about ½” long by 1/8” wide, according to John Roberts, director of healthcare for the UCC. That compares to 1½” x 1” for the conventional Universal Product Code that displays only the NDC.

Other RSS pressure

Roberts says that the RSS specification will become an international standard in the first quarter of 2002 when the EAN.UCC System, the international standards body, adopts it. That step will probably force U.S. manufacturers—regardless of what the FDA does—to use the RSS code on all unit-of-use and larger packages.

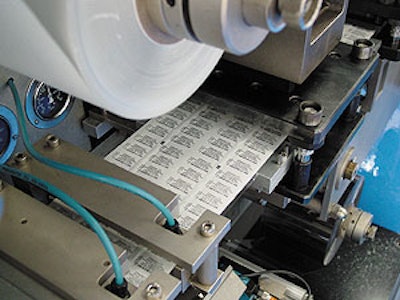

But Roberts does not think that will be a problem. New York-based drug maker Pfizer already successfully tested application of the RSS code on blister packs in a lab and is now testing it on production runs, according to Roberts.

An encompassing FDA requirement for RSS coding will force many packagers to invest in production line software and new in-line printers and scanners. These will be needed for bottle labels as well as blister packs and single-use products such as syringes.

The FDA’s preliminary estimate is that any new rule would cost between $500 million and $1.4 billion over a 10-year period. The wide range in the cost estimate reflects the agency’s uncertainty as to the costs associated with various pieces of information that might go into a bar code, whether all or some human drug products and biological products are bar coded.

Cost or benefit

Ron Barenburg, vice president of business development for International Barcode Corp. (New York, NY), says, “The costs are not as daunting as some people would have you believe.” IBC provides turnkey bar-coding systems to pharmaceutical companies. In any case, his appraisal does not include the costs of the new packaging lines that GSK’s Cohen believes will be required.

Groups lined up behind expanded bar coding are less concerned about new costs manufacturers may incur and more concerned about what they see as bar coding’s positive impact on health outcomes and health insurance costs. “We see it as a safety issue in reducing medication errors, and a way to reduce the social and economic costs associated with those errors,” says Gary Stein, director of federal regulatory affairs for the American Society of Health-Systems Pharmacists (ASHP).

Stein says costs will depend on how much information is required in the bar code, mentioning FDA’s estimate of between $500 million and $1.4 billion over 10 years. But that figure is dwarfed, he points out, by the annual costs associated with errors in administering prescription drugs.

The FDA will referee the fight between PhRMA and the ASHP and its allies such as the American Medical Assn. Don’t expect a knockout blow from either. The proposal will go forward, probably with numerous concessions to the drug companies to ease the transition.