For Häfele America Co., a furniture hardware distributor headquartered in Berlin, Germany, business is booming. But until last August, its bag labeling method wasn't keeping pace with increased customer demand.

Häfele's Archdale, NC, Repackaging Div. provides bagged hardware kits with items including handles, knobs, nuts, bolts and screws to companies that manufacture ready-to-assemble furniture. For small runs or irregularly sized bags of hardware, operators at Häfele had been hand-labeling the linear low-density polyethylene bags in web form and sending them through tabletop baggers. Large runs go through fully automated labeling, filling and sealing equipment.

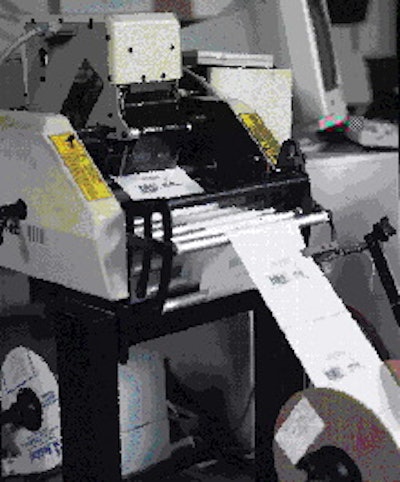

During the last three years, however, volume at Häfele has more than doubled, from 1.4 million packages/yr to 3 million. Employees who hand-applied the pressure-sensitive labels to the bags couldn't keep up. Working with distributor Associated Packaging (Statesville, NC), Repackaging Div. manager Bob Hough found the PrintPro(TM) Sonic(TM) thermal-transfer printer from Comstar Printing Solutions (Streetsboro, OH) to be an easy solution. "Basically we saw an easier way to get things done quicker, and we jumped on it," Hough says.

Keeping pace

Since the machine's installation last August, product information is printed directly onto the bags instead of onto labels. The result is a crisper, more professional look due to the Sonic's 300-dpi printhead and print registration accuracy of 1/16". The printer is used in conjunction with Häfele's five existing PaceSetter(TM) 55 tabletop baggers from Automated Packaging Systems (Streetsboro, OH).

To determine if the Sonic and the PaceSetters are needed for a particular bag/product, Hough evaluates each individual job that comes into the facility. If the order is a short run, from 500 to 1ꯠ bags, or if the large and bulky size of the merchandise would not work well with automatic bagging machinery, the job is assigned to the Sonic/PaceSetter combo. First is off-line imprinting on the Sonic.

Label formats are stored on a PC, which is connected directly to the Sonic through a data port. The imprint information is either pulled from memory, or if it is a new job, a new imprint is created. Next, the bags-on-a-roll are loaded into the Sonic. The Autobags® from Automated Packaging are made from film ranging in thickness from 2 to 4 mils. Sizes range from 4"x4" to 6"x10". All printing is done in black at speeds from 60 to 120 bags/min for medium-sized bags and up to 200 bags/min for smaller bags.

Once printed, bags are rewound on a spool, and the spool is mounted on the PaceSetter. Operators stationed in front of the baggers use foot controls to open the bags with compressed air and then insert the items needed in each bag by hand. The operator then slides the bag into a slot and pushes down on a bar to heat seal the bag at 6 bags/min. The bag then drops into a corrugated shipper. Häfele usually packages 50 bags/shipper.

Saving money

Although Hough wouldn't quantify his cost savings since the new equipment arrived, he did say the savings are significant. "I'm saving money on labels I don't have to buy, and I'm saving money on labor that I no longer have to exert to put labels on the bag," he says. Hough says he has cut label usage in half. Labels are still used on individual bags that are too large to fit on any of the machines.

According to Hough, before switching to the Sonic, Häfele employees would package an average of 900 bags/day. Now they produce more than 1꺜 bags/day. "Once we started using the Sonic, it was a mystery to me why we didn't purchase one long ago," he says. "Now, our operators can get right to work filling the bags with product and don't have to go through the extra step of hand-labeling each bag. It has made our packaging much easier." (LB)