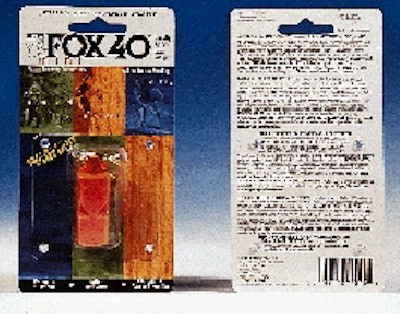

After being let down one too many times by a whistle that malfunctioned during a crucial play, Ron Foxcroft, a professional referee, decided to build himself a better mousetrap. His resulting "pealess" whistle-which omits the cork pea that can become frozen, wet or "overblown," all contributing to whistle failure-launched a new company, Fox 40. Today Fox 40 whistles are sold in over 120 countries, typically merchandised in blister cards with heat-sealed polyvinyl chloride blisters. In the U.S., they're available at sporting goods and outdoor stores for $5.99.

However, in some markets, notably Europe, paperboard blister cards aren't considered recyclable since they're coated with plastic for heat-sealing.

"We were having a hard time bringing blister packs into Germany," explains Paul Groleau, operations manager for the Hamilton, Ontario, Canada, firm. "Our customer was placing them into plastic bags so that they could be recycled, but which didn't do anything for the shelf appeal of the product." He adds, "A lot of our customers are expecting and requiring recyclable packaging." Thus, the company began to look for a new package.

"We wanted a 100 percent recyclable card and blister, and we wanted a product that could be pilfer-resistent," says Groleau. "Plus it had to have retail appeal at the same time."

The solution was a type of blister pack that still uses a clay-coated, 100% recycled newsback card and clear plastic blister (thermoformed now of recycled polyethylene terephthalate glycol), but which uses a mechanical technique to adhere the two components. Essentially, four posts or protrusions are designed into the plastic thermoformed blister. Similarly, four matching holes are die-cut into the card. A unique blister packaging machine, called the Kordpak II, supplied by Kord Products Ltd. (Brampton, Ontario, Canada), guides the protrusions into the holes. It then applies pressure to flatten the protrusions so that they mushroom over the holes, thus mechanically locking the blister to the card. The Swedish-built machine has been running since March.

Aside from meeting the objective of producing a recyclable blister pack without sacrificing merchandisability, the new package and machine provide Fox 40 with two big benefits.

First, the cards cost about 20% less than before since they don't need to be coated with plastic. (There's nothing especially unique about the cards themselves, says Groleau, except for the fact that they're now made of 24-pt, 100% recycled newsback versus virgin SBS used previously.) Fox 40 also chose to switch to PETG, which is only slightly cheaper than PVC, but is more widely accepted for recycling. It also contains 100% recycled content.

The cards have an environmental message on the back touting the recyclability, and Groleau says plans call for the blisters to be thermoformed with the SPI-1 code for PET recyclability.

Next, the machine itself is far more productive than the semi-automatic blister sealer that Fox 40 had been using. That unit had been producing about 1ꯠ packs/hr with two people. Today, the Kordpak II produces about 1귔 packs/hr with one person. Since the machine packages cards two-up, that translates into a cycle time of just over 12 cycles/min or about 25 cards/min. Fox 40 expects the labor savings to pay for the machine in two years or less.

And that's not considered the upper limit, says Groleau. "We're still learning on this machine. The operators are finding they can speed the machine up as they get comfortable with how it operates."

There are two keys to the increase in speed. First, the Kordpak II automatically places blisters and cards. On the old machine, those steps were manual. (On the new machine, as on the old, the operator still loads the whistles into the blisters.)

The other key to a speed increase is that the machine doesn't have to dwell on a heat-seal. The compression of the blister's protrusions is instantaneous.

Groleau also points out that because the machine is linear as opposed to rotary, there's room to add up to three more operators to load product into blisters if production needs to be shifted into high gear. If necessary, Fox 40 expects to reach speeds of 2ꯠ packages/hr this way.

Small footprint

The machine itself has about a 25% smaller footprint compared to the previous rotary-style machines, says Groleau. At the beginning of the in-line system, two side-by-side pairs of vacuum cups on a pneumatically driven assembly-one pair per blister-pluck a pair of blisters from the dual magazines. The vacuum cups swing down and deposit the blisters face down, precisely in a two-up nest. The four protrusions on the blister catch four corresponding posts that stick out of the nest and hold the blister in place.

The nest, built into a conveyor, advances to the next station, where an operator manually loads a whistle and accessory items such as lanyards. The nests then advance down to card placement. There, another vacuum cup assembly, similar to that used for the blisters, grabs two cards and places them face down over the open blisters.

The nest advances to a compression station where a metal plate swings down and flattens the protrusions, forcing them to mushroom around the holes in the cards.

Finished blister packs are ejected into an in-process bin for subsequent manual case-packing.

The key to the machine is its ability to consistently match up the four die-cut holes on the cards with the four protrusions on the blister. Groleau swears that he hasn't experienced any significant problems with misaligned cards.

"The engineering of the machine is incredible," he says. "I've never really seen anything that comes close to it. The set-up time was nothing," says Groleau. "We were operational by the first afternoon."

Total changeover time is a wash, according to Groleau. While it takes 20 minutes to about a half hour to swap out the nests for a different size, such changeover needs to be done only once a day versus three to six times per day previously (albeit at only five or 10 minutes per change). That's because about 70% of the cards can be used on one set of tooling, with the remainder on the other. On the previous blister sealer, 15 different sets of fixtures were necessary, one for each card size. The difference is that the nests on the Kordpak II can accommodate several variations in the shape of the blister, whereas the previous machine required separate tooling for each blister.

In terms of possible drawbacks, Groleau concedes that pilfer-resistance had been an issue with early prototypes, since the blister originally could be easily disengaged from the card.

"We went through a couple of stages in the beginning where we had to take a second look at it and improve on the original idea, which I think is where we're at now," says Groleau.

"Kord's been a big help in that issue. We brought a couple of issues to the table, and they readily accepted them and improved them. Of course, if someone wants the product bad enough, they'll get it. But we were pretty pleased with the pilfer-resistance in the final version," he says.

Having used up nearly all of the old heat-seal blister packaging materials, Fox 40 has moved the bulk of its production to the new packaging, which the company plans to use for all markets, not just Europe.

Although it's too early to tell the impact on sales, Groleau says early feedback has been positive.

"Our first customer to receive this new packaging was our biggest customer, located in Japan, and they were extremely happy with it."