With aseptic packaging technology adding weeks and even months to the shelf life of dairy products, more dairies are beginning to rely on this technology to conquer distant markets previously out of reach. In Germany, market leader Ehrmann purchased two fully automatic aseptic thermoform/ fill/seal packaging lines for just such an expansion. The equipment is manufactured by Germany's Adolf Illig Maschinenbau GmbH, represented in the U.S. by Interpak, LLC (Chattanooga, TN). Both packaging lines were installed in Ehrmann's new plant in Freiberg, Germany. The newest line began production in March '96.

Headquartered in Ober-schnegg, Germany, Ehr-mann is the number one producer in Germany of yogurt, puddings and dairy dessert products. Ehrmann purchased the machines in order to expand distribution into other parts of Europe, especially East block countries like Poland, Czechoslovakia and Russia. Since such countries often lack refrigerated distribution chains, it was essential for Ehrmann to produce aseptically packed dairy products that don't require refrigeration in order to access these markets.

Before aseptic packing, Ehrmann's products had a 30-day shelf life under refrigeration. Products packaged on the new lines in Freiberg have a 130-day shelf life without refrigeration. Aseptically packed products are sterilized, and merchandised mostly in refrigerated cases at retail in Western European markets, though that's more for consumer acceptance than product protection. The equipment is so successful that Ehrmann has ordered a third system, with delivery expected in the spring.

Products packed on this machine include yogurts, puddings and dairy desserts. All products are filled in 125-mL thermoformed polystyrene cups, which are lidded with foil. Materials are conventional, and are sourced locally. Ehrmann produces only four-packs since they're popular, though the equipment is capable of producing two-packs.

Steam-only filler sterilization

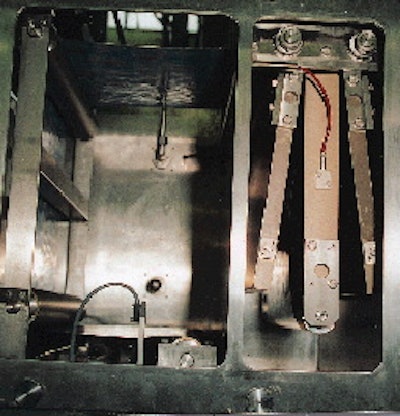

What separates these systems from other aseptic tf/f/s lines, according to Illig, has to do with how it sterilizes the filler. Only high-pressure steam is used-at 1400C (2840F), 3 bar pressure, for 30 min-instead of hydrogen peroxide (H2O2). H2O2 is used solely for sterilizing the packaging materials, not the filler. Result: Ehrmann can package product without having to continuously clean the filling area with chemicals.

A second benefit is the way the system sterilizes the PS sheet and foil lidding materials. After sterilization in the H2O2 solution in a sterile bath chamber, the materals are not directly fed into the aseptic filling chamber. Instead, H2O2 residues evaporate in a special sterile heating section-entirely separate from the multi-zone contact heater that heats the thermoforming material.

This separate heating section allows Illig to guarantee a peroxide residue in the cups during filling of less than 0.1 ppm. The manufacturer also guarantees a sterility level of 1:10ꯠ, meaning that fewer than 1 in 10ꯠ cups will be unsterile. In actuality, Illig says sterility levels are much higher, 1:100ꯠ or better.

Minimizing waste

Another special feature of the machine is automatic positioning of the sealing and die-cutting station. That eliminates waste during starts, stops and restarts. It relies on fiber-optic sensors to detect cup position. If the material has shrunk during a long stop, or if the cups are somehow not in the correct position, the sensors signal the PLC, which in turn signals the sealing and/or die-cutting stations to automatically reposition themselves to be centrally located over the cups.

While providing accurate sealing and cutting, it also means there's never a loss of material after a machine stop, nor are cups accidentally squeezed in the sealing or die-cutting station, according to Herbert Schex, plant manager at Ehrmann's Freiberg plant. Also minimizing material usage is the multiple gripper transport system, which requires only a 10-mm margin of material on both sides of the web.

Packaging starts out as 51-mil PS sheet, from several suppliers, unwinds from rollstock. The material enters the sterile bath chamber and is exposed to the hydrogen peroxide solution of water that's 35% H2O2, at a temperature of 60°C (140°F).

The aseptic module that controls the sterile baths for the container and lidding in each of the hermetically sealed chambers is supplied by MTS Milchtechnik AG (Speicher, Switzerland). The same unit also generates the sterile air and controls the aseptic atmosphere within the machine during production. Finally, it controls the CIP/SIP cleaning functions.

From the sterile bath, the cup material then enters the sterile heater section-separate from the standard material pre-heating section-allowing the H2O2 residues to evaporate at a temperature of 80°C (176°F). That's when the material is ready to enter the preheat section of the thermoformer, located in the f/f/s area.

Four-zone heating

Inside the form/fill/seal area, a steady overpressure of sterile air, supplied by the external aseptic module, maintains sterility during packaging. The material is pre-heated prior to thermoforming by four separate heating zones set at progressively higher temperatures. Each zone is the length of one index of 24 cups (six across and four in the machine direction). When heated to forming temperature, the material indexes out of the last zone and into the forming station. Forming consists of a pre-stretching phase by plug assist followed by final forming via sterile pressurized air. Uninterrupted material gripper rails hold onto the material at all times for maximum control during heating. The benefit: no random shrinkage of material. The web of cups then indexes into the filling station.

There are actually two 24-head filling units positioned in sequence. They are used simultaneously when Ehrmann fills a product requiring a different bottom or top layer. Only one of the filling units is used when layers aren't called for.

For compatibility with the aseptic packaging environment, the filler relies on ceramic pistons and non-wearing seals that are resistant to germ contamination. It is a piston dosing unit that drains product from a funnel in a vertical operation and then pushes out the product via a series of valves that fill 24 cups per cycle. Filling accuracy is ±1%, according to Ehrmann. Though it can operate as fast as 36ꯠ cups/hr, Erhmann typically runs it in the range of 28ꯠ to 30ꯠ cups/hr.

After filling, the web of cups indexes into the sealing station. By this time, lidding material, which has gone through its own H2O2 sterile bath, is sealed onto the cups via heat and pressure. Lidding, also from several suppliers, is a 1.6-mil structure consisting of aluminum foil with a heat-sealing lacquer, and is gravure-printed in three to eight colors, depending on the product.

Finally, the cups are die-cut into four-packs with a flat die. The multipacks exit the thermoformer and are conveyed to a Krones (Franklin, WI) wipe-on labeler that applies two front labels to the front two cups and separate rear labels to the back two cups. The paper labels are applied with cold glue adhesive.

The four-packs are conveyed into an automatic wraparound case-packer, sourced locally, that loads the desired number of multipacks and seals the case with hot melt adhesive. Cases are automatically palletized and stretch wrapped for distribution. The entire line, controlled by a Siemens (Alpharetta, GA) Model S5 115U PLC, features fully automatic operation, and usually requires only one operator per line-from forming through labeling-to restock materials.

Automatic CIP/SIP

Since each of the two lines is dedicated to a particular product, clean-in-place only needs to be conducted once per week, which takes about 31/2 hr, according to Schex. Sterilize-in-place takes an additional 31/2 hr. Flavor changes, which are done more frequently, require only a 1-hr CIP procedure.

"The cleaning can be selected by a special program for the product change and runs automatically," explains Schex. "For the time being, manual action is necessary for cleaning the funnels, though this will be automatic on the new machine [on order]."

Schex says that uptime efficiency on the equipment is in the 92% to 95% range, a figure with which Ehrmann is pleased. "Illig machines were purchased because a cooperation has developed for many years which is successful and satisfying for both parties," comments Schex. "Illig met all our demands with respect to machine technology."