Pharmaceutical packagers need help complying with increasingly burdensome process-validation requirements to comply with FDA and other governmental regulatory organizations, according to representatives from Pharmacia and Abbott Laboratories Italia who presented at the Heart of Packaging symposium held in Bologna, Italy, in late September.

Robert Martell of Pharmacia, Kalamazoo, MI, said packaging machine builders can help reduce the cost and time it takes to implement packaging FDA-compliance requirements for each product. He said controlling validation costs, which can range from 10% to 40% of an entire project’s cost, is critical.

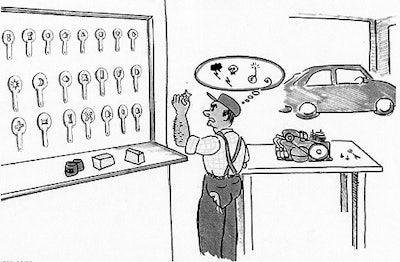

To explain the difficulty pharmaceutical companies face in validating machinery, Giuseppe Motta of Abbott Laboratories Italia used a car mechanic as an example. He said car mechanics have standard components, such as a wrench to adjust car parts. Pharmaceutical engineers, however, need different “wrenches” to adjust different machines to each product requirement (see illustration). This leads to a much more complicated validation process.

According to Martell, machinery builders can help simplify the validation process by leveraging servo capability, building upon industry-standard platforms, and integrating logic and motion controls in a single-control environment. As for design methodology, Martell said a clear representation of all machine states, industry-standard software, and a well-documented design approach can go a long way.

As an example of a standard design methodology, Martell specifically referred to the state model being developed by OMAC’s PackML team. The model describes whether a packaging machine is running, down, on standby, etc. Machines that are PackML-aware can reduce the time it takes to integrate on a packaging line. If PackML is widely adopted by automation suppliers and machine builders, it can standardize the way machines are integrated on a line, no matter the type of product being packaged or the location of the plant. For the pharmaceutical industry, such standardization can theoretically lead to simpler validation, according to Martell.

Both Martell and Motta mentioned that the path to easier validation could be shortened by more collaboration between original equipment manufacturers, technology suppliers, and end users.

For an overview of the "Heart of Packaging" conferences, see: packworld.com/go/w043