This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

This unique technology prevents the ink in a printer from drying out even during prolonged breaks in production.

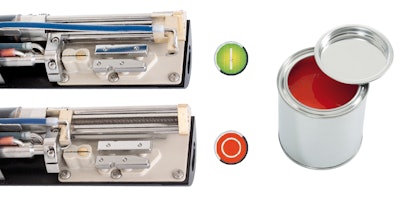

The automated "Sealtronic" nozzle seal allows the company to meet the highest standards of reliability for industrial inkjet printers. Using the Sealtronic system, the nozzle and gutter form an airtight circuit whenever the printer is not being used for coding. No ink can leak out of the circuit and no air can get in. This keeps the ink fluid at all times – just like a sealed paint can – and the CIJ printer is always ready to go. Just a single push of a button starts the Leibinger printer, and it is ready to print in less than a minute. All Leibinger small character inkjet printers from the JET3 and JET2neo series come standard with the automated "Sealtronic" nozzle seal! The Leibinger JET3pro is particularly well-suited for the food and beverage industry. The printer features the IP65 protection class, making it ideal for wet or dusty production environments.

Leibinger recently brought four new inks onto the market for its inkjet printers: Two MEK-free inks in red and blue and two inks that meet the strict requirements of the U.S. Food and Drug Administration (FDA). The first FDA-compliant ink is specifically suited for coding eggshells. The second FDA-compliant ink can be used for coding foodstuffs directly, e.g. for promotional activities. The ink is also ideal for applications that contact foodstuffs directly, such as coding the insides of food packaging. Consuming the ink is completely safe.

Leibinger inkjet coders can print on any conceivable products such as carton, plastic, metal or glass and materials, no matter whether the surfaces are flat, rough or convex. Imprinting is based on the continuous inkjet principle: No contact during ongoing production while using quick-drying inks. Sample patterns and patterns brought by customers will be printed at the trade show booth.