This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

Test results from Lion Precision, who provides label sensors using all these technologies, show distinct differences in regard to registration accuracy. “There are several different advantages and disadvantages to each technology,” according to Mark Kretschmar, communication manager for Lion Precision. “The typical end-user or machine designer doesn’t have the time or inclination to search out the differences for such a small piece of the labeling system, but the differences can matter, especially at higher speeds. As the leading clear label sensor provider, we felt compelled to discover and share the accuracies of each of our technologies.”

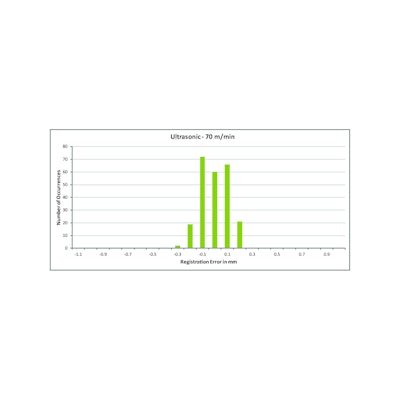

Lion Precision designed and built a machine that uses a rotary encoder and a gear belt to precisely control and measure the location of label edges on a loop of ordinary paper labels. The system is capable of measuring label edge position with better than one micron of accuracy. Sensors using each of the four technologies were tested on the device with web speeds of 70 meters/minute and 220 meters/minute and compared. “The results were very clear,” said Kretschmar. “The capacitive technology registered no errors, even at 220 meters-per-minute.” Optical sensors showed a small decrease in accuracy at the higher speed. Ultrasonic sensors, while having the advantage of working with a very wide range of label materials, showed considerably larger errors and a clear relationship between web speed and registration accuracy. Kretschmar cautions, “Registration accuracy is not the only factor in making a label sensor choice. Each technology can struggle with certain types of label and liner materials and have different setup procedures.” If registration accuracy is of paramount importance, ultrasonic sensors are not the best choice, especially at higher speeds. If using slower speeds and the primary concern is usability on the widest range of materials, ultrasonic may be a good choice.

Lion Precision’s newest label sensor, the LRD8200 uses ultrasonic technology. “It isn’t always about having the latest gadget or technology,” according to company president, Don Martin. “For users concerned with registration accuracy at high speeds, we steer them toward the capacitive sensors because they will get better results, even though they aren’t the newest product.”

Detailed results of the test are available as a web page or PDF at a new site dedicated to helping users make the best sensor choice.