Essroc, headquartered in Nazareth, PA, is part of Italcementi Group, Bergamo, Italy, one of the world’s leading cement producers. The company operates nine production facilities in the U.S., Canada, and Puerto Rico, primarily supplying cement products to contractors. Currently, Essroc is building a new $500 million state-of-the-art plant around an existing facility in Martinsburg, WV. The new plant is scheduled to be completed by spring 2010.

Traditionally, cement plants encounter vibrations from nearby quarry blasting and heavy equipment used for stone crushing and grinding processes. The packaging systems within the facility must be durable to tolerate these conditions. So when Essroc evaluated new marking systems for printing the date and shift on large bags of powdered cement packed at its Martinsburg plant, a rugged design was essential.

Essroc needed a rugged printer that would be easy to use and could deliver consistent- quality printing on its heavy-duty, film-lined, kraft brown bags (75-, 80-, and 94-lb volumes). Keith Hirsch, packing and shipping supervisor for Essroc, notes, “We had an outdated ink-jet system that was not user-friendly. And we had several customers complaining that the printing was hard to read and didn’t look professional.”

Hirsch also wanted a marking system that could integrate easily into the new packaging line and be flexible to accommodate anticipated doubling or tripling of growth in production output.

Essroc had previous good experience with Matthews marking systems. In 2006, Essroc installed three I-Mark V80s (the predecessor to the V84), at its plant in Fort Royal, VA.

After reviewing various options, Hirsch selected a system from Matthews Marking Products (www.matthewsmarkingproducts.com) that includes an I-Mark™ V84 controller with an 8000 Series 16-valve “midi” Drop-on-Demand (DOD) ink-jet printhead.

The system was installed in June 2008. When the printing system was installed, it was programmed so that no manual change of the print message was required. Between 8 a.m. and 4 p.m., it prints message A. At 4 p.m., it switches to message B and at midnight, it starts message C for the night shift. Hirsch says, “It’s great. All we have to do is restock the ink when it runs low and clean the printhead every three to five days, depending on usage.”

Printing performance

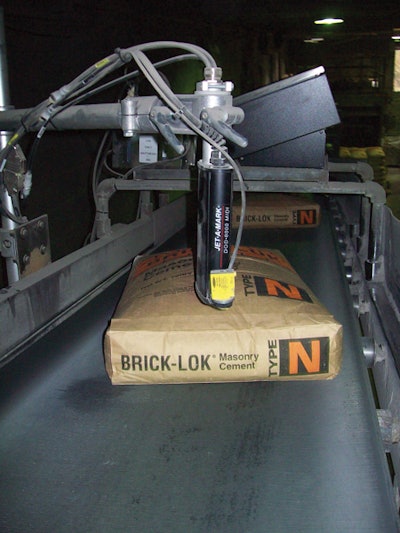

The Matthews printer is mounted on the conveyor belt. Flexibility is key. The printhead is adjustable so that when different bag sizes are running, the height and width of the print area can be quickly changed to fit the application.

The cement powder comes from a silo to a hopper and is fed into spouts. Preprinted bags are stacked behind each operator. A self-sealing bag is manually placed on the weight-sensitive spout. When the target weight is reached, the bag is automatically sealed and drops onto a conveyor belt. Essroc is in transition for some of its bags and filling systems, so these supplier names were not disclosed.

The V84’s 10.4-in color touchscreen interface allows independent control of up to four printheads, although Essroc currently only uses one. The system is readily expandable and adjustable as production requirements grow and when Essroc needs to print more than the date and shift code data used now. Printed characters may be from 3⁄32 in. to 5 in.

The maximum speed of the V84 is 680 fpm—more than the projected speed requirements for the new Martinsburg plant. And the Matthews 8000 Series printheads, driven by the V84, have the added benefit of low ink consumption and sharp, clear printing with quick-dry inks.

Summing up, Hirsch says, “We are very happy with the relationship we’ve developed with Matthews and with the performance of the equipment. The new Matthews system is working very well. The print quality is good. It’s easy to clean and maintain. And it’s very user-friendly.”