Triangle Package Machinery Company

Chicago, IL 60707-2293

We’ve been your trusted partner in packaging since 1923. For three generations, our family-owned and operated business has provided innovative sanitary packaging solutions that are built to last and supported in the USA.

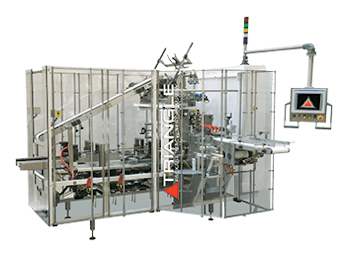

VFFS bag machines, pre-made pouch fillers, bag-in-box cartoners, multihead weighers

Machines include 1-year warranty from date of installation (excludes wear items and neglect). Major components are warranted as from OEM.

Our Technical Support Team includes 22 fully-trained Triangle Service Technicians with an average of 18 years of experience servicing Triangle equipment. Our service technicians are based in Chicago and throughout North America. Customer service reps are on call 24 hours/day. And, our Parts Department offers an extensive inventory; most parts shipped within 24 hours. Along with available on-line troubleshooting, we can keep you up and running 24/7.

Operator, Mechanical/Electrical, and Programming Training. Available in your facility or ours. Bilingual instructors available, as well as FSMA consultation. Training includes comprehensive training manuals, multimedia presentations, and certificates of completion.

From vertical form fill seal baggers (VFFS) to bag-in-box cartoners, pre-made pouch fillers and multihead weighers, Triangle covers all your food-safe packaging needs. Triangle sanitary packaging machines offer versatility while providing solutions that maximize production. Whether you need to weigh or bag seafood, mashed potatoes, baking mix, put a bag of cereal in a box or a variety of other products, there’s a Triangle solution engineered to meet your application.

Triangle Package Machinery Company has been your trusted partner in packaging since 1923. The U.S.-based, family-owned and operated company proudly offers fully customizable packaging equipment for all applications–from filling baking mixes, mashed potatoes and shrimp, to putting a bag of cereal or rice in a box. These machines are designed for everything from dry, to harsh, to washdown environments, including vertical form-fill-seal (VFFS) bag machines, multihead weighers, bag-in-box cartoners and pre-made pouch machines. Its sanitary packaging equipment for food is available in several levels of sanitation to provide products with the food safety requirements they need, including painted steel, stainless steel, stainless steel washdown and USDA/3-A. Triangle makes and ships all parts directly from its 120,000-square-foot manufacturing facility in Chicago. A century after its founding, Triangle’s third and fourth generations use its legacy of expertise to continue keeping food safe with proven engineering, quality manufacturing and superior customer service. The company’s durable, accessible machines endure the test of time while being backed by a knowledgeable regional support team.

Visit www.trianglepackage.com for more information.