This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

CarnaudMetalbox Engineering Ltd. (CMB Engineering), a leading manufacturer of canmaking technology has launched the Sovereign DecoratorTM, a high-quality can decorating machine engineered to produce flawlessly decorated beverage cans at high speed. The new premium decorator is designed to reduce changeover time for can manufacturers who produce high volumes of cans in short runs while minimizing spoilage and saving ink.

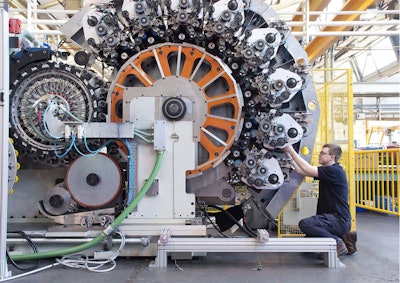

The Sovereign Decorator uses up to eight colors to enable beverage can manufacturers to offer brand owners more sophisticated and distinctive designs than ever before. Using unique, oscillating rubber rollers the decorator offers smooth and even printing. The print rollers’ oscillating speeds can be individually fine-tuned to allow the inkers to work efficiently with any ink color or viscosity. The Sovereign Decorator has an innovative linear bearing spindle disc design that applies consistent mandrel-to-blanket pressure to the can surface during the printing process, maintaining a high print quality. The decorator inkers also feature anti-ghosting rollers, eliminating the occurrence of ghosted images.

For added flexibility and efficiency on the production line, the Sovereign Decorator features an innovative infeed and outfeed design that improves the loading and discharge of cans, increasing throughput speeds and simplifying can size changeovers for operators. The Sovereign Decorator rollers can be programmed for new inks and graphics using a library of printing recipes to facilitate fast, straightforward label changes. Operators can adjust printing programs and label registration while the machine is running, further minimizing production downtime.

The Sovereign Decorator has several features to reduce ink and spoilage. If the can is not correctly aligned, the automated rejection system removes it from the production line before the printing process, minimizing the number of incorrectly decorated cans. The system¹s new, pneumatic single mandrel trip ensures that only the substandard can is rejected, further reducing spoilage for beverage manufacturers. The Sovereign Decorator¹s innovative ductor rolls, which take the ink from the fountains to the printing system, are fully adjustable according to the amount of ink required for a design.

Rather than using gears in the inker drives the Sovereign Decorator uses belt drives, which require no lubrication, eliminating oil leaks, and reduce vibration. These minimize downtime due to maintenance while increasing can print quality. The system’s linear bearing spindle disc has been developed for maximum stability giving a consistent mandrel circle. The design allows for minimum print pressures to optimize decoration quality. The linear bearing spindle disc also minimizes pressure needed during the printing process so wear is minimal and lifetime maximized.

The Sovereign Decorator comes with safety guards to protect operators using the machine and has received European CE Mark safety certification.