Those who know the sport of rugby are familiar enough with the meaning of the word “scrum,” the bunched-up group of players into which the ball is thrown so that play can resume. But the term is also heard in IT and business circles these days to describe a set of practices used in agile project management where great emphasis is placed on multidisciplinary participation, daily communication, and the flexible reassessment of plans.

Spend a day split between Procter & Gamble’s Cincinnati headquarters and its nearby Beckett Ridge Technical Center and two things become abundantly clear. First, the scrum is a model that is enthusiastically embraced and used as a tool to bring innovation to life—a key focus for P&G. And second, packaging is smack dab in the middle of the scrum. Kathy Fish, Chief Research, Development, and Innovation Officer, says it’s all about lean.

From left: Ken McGuire, Research Fellow; Phil Duncan, Chief Design Officer; Victor Aguilar, Vice President Corporate Technology Development and Open Innovation; Kathy Fish, Chief Research, Development, and Innovation Officer.

From left: Ken McGuire, Research Fellow; Phil Duncan, Chief Design Officer; Victor Aguilar, Vice President Corporate Technology Development and Open Innovation; Kathy Fish, Chief Research, Development, and Innovation Officer.

A 40-year veteran of P&G, Fish is a senior member of the Global Leadership Council (GLC) and leader of R&D, which discovers, develops, and implements technologies to accelerate and advance the work of P&G brands that make up the 10 category-based Global Business Units. At the same level of the corporate structure and also part of GLC is Phil Duncan, Chief Design Officer at P&G for the past 11 years. An equally big fan of the scrum approach, Duncan summarizes its biggest benefit more pithily. New developments coming out of the pipeline, he says, are “Months in the making.”

The other thing that becomes clear in visiting with the likes of Fish and Duncan is that packaging at P&G is always viewed in terms of how it meshes with four other key business drivers. P&G refers to these as the five vectors of superiority: product, packaging, brand communication, retail execution, and value that can be appreciated by both consumer and retailer. Collectively, they are the compass by which the P&G ship is steered.

“A few years back,” Fish explains, “at a point where we weren’t really meeting our growth goals, we carefully studied the success factors behind our billion-dollar brands. And what became clear is that those successful brands weren’t just better than the competition, they were irresistibly superior. They were so superior that they made an emotional connection with consumers, to the point that consumers really missed having that brand in their lives if they switched to another brand. We came to realize that what we had done so well with these billion-dollar brands was that we had taken a holistic approach that made the whole consumer experience with the brand seamless. Naturally, at the most fundamental level it was a matter of product and packaging working together. But aside from product and packaging we’ve come to see that it’s really more than that, so we’re now focused on also integrating the retail experience, the value equation, and the commercialization and marketing in such a way that the consumer experience is completely seamless from the time they first see the item to the moment they are shopping to their use of it in the home to when they tell their friends about it.”

Innovation reset

Duncan says it was partly a matter of rethinking the role of innovation. “We’ve always understood that innovation is the lifeblood of the company and a key differentiator in terms of how we win against the competition,” he points out. “But we needed to do a better job of understanding how product, package, design, and ideas should mesh. So we did a lot of thinking about how the skills within our organization—R&D, design, commercial functions—needed to come together to make that happen. Whereas in the past we might have been content to think about it as ‘If we can just get the product into her or his hands, they’ll love it.’”

Fish adds that with the new mindset came a significant financial investment. “We invested in design within the R&D organization to help make sure that we are really crafting holistic experiences from the very beginning. We’re now able to rapidly prototype, test things out very quickly with consumers, and make a decision.”

Victor Aguilar, with 30 years under his belt at P&G, reports to Fish and recently moved into the position of Vice President Corporate Technology Development and Open Innovation. He elaborates on how the five vectors of superiority shape packaging design. “We’re in the business of creating superior consumer experiences. We call them irresistibly superior experiences. The whole idea is that consumers fall in love with the products we create, and that includes, of course, the packaging execution. To us the package is never just a container, because it’s part of our brand-building story, part of the holistic consumer experience we seek to create.”

Fish is in complete agreement with Aguilar’s take on packaging. “It’s so much more than a container,” she says. “Is it easy to hold and use? Does it pour well? Is it responsible from a sustainable packaging perspective? Remember, too, that not everybody sees our advertising these days, so the burden on the package to tell the story to the consumer is more important than ever. It needs to have the consumer in the store saying ‘I know what you are. I know which version to select. And I want to buy you because you look really compelling.’”

The unique dispensing technology and the refill format that characterize this recently launched product were first commercialized under the banner of the Febreze brand. P&G describes this as an important packaging platform that we’re going to leverage.”

The unique dispensing technology and the refill format that characterize this recently launched product were first commercialized under the banner of the Febreze brand. P&G describes this as an important packaging platform that we’re going to leverage.”

“We had to raise the bar if we hoped to offer products that really stand out, and this is where the intersection between product formulation and packaging execution comes in,” says Aguilar. He adds that in his new role as corporate technology development leader, his job is to look into the future not just of packaging but of innovation in general. “At the corporate level we’re looking five to ten years ahead of our Global Business Units. In the case of packaging in particular, we’re putting a lot of effort into sustainability and e-commerce.”

The scrum in action

When asked to provide a good example of the scrum approach that characterizes P&G’s path to innovation, Aguilar points to the injection/stretch blow-molded PET bottle for Lenor brand fabric softener—the U.K. equivalent of the Downy brand so well known in the U.S. The package design team gave it a diamond-faceted look so that it would stand out on shelf, and industrial designers ensured that these shapes would lend top-load strength to the bottle and thus reduce the amount of plastic resin required to make the bottle. This reduction in plastic used means that the vector of superiority relating to value is represented; it also scores some sustainability points. Meanwhile, the product formulation team paid close attention to product viscosity and concentration so that the package’s shape and its cap were compatible with pouring and measuring. As for the final two vectors of superiority, messaging and retail execution, they’re in the mix through advertising and in-store aisle-end displays. And what’s most important is that it all gets baked in from the get-go.

“While functions such as design, marketing, and R&D are still independent entities, we now have integrated work processes that result in tightly integrated development,” says Aguilar.

He points to the AeroFlex concept, winner of the top award in the 2018 Dow Awards for Packaging Innovation, as another good example. A number of commercially available products in this breakthrough format are being tested, including P&G’s own Dawn brand 9-oz dish soap (for complete coverage, go to pwgo.to/5313).

Though it looks a lot like any other flat-bottom, gusseted, stand-up pouch, it utilizes nitrogen gas to inflate specific portions of the pouch, notably along the edges, to bring a degree of rigidity that is typically not possible in a flexible package. And because the package is made of flexible film, it requires 50% less plastic than a traditional blow-molded bottle. Not to mention that, because it can be delivered to a filling facility as rollstock, it has the potential to score additional sustainable packaging points because it greatly reduces the number of truckloads of empty bottles that have to be delivered.

“Only through a tightly integrated and multidisciplinary approach to development could such a product and package emerge,” says Aguilar.

The Dawn brand dish soap execution of this innovative technology is a good example of what P&G refers to as a “landing strip.” As a new technology is developed, P&G corporate picks the business unit most suitable to land that technology in the marketplace on a commercial basis. Once it’s established there, some well-organized internal networking kicks in so that other business units can consider it for commercialization. This is how, not long after the Dawn product debuted in the AeroFlexx format, Old Spice brand men’s body wash appeared in an AeroFlexx format.

A similar landing strip execution was the 2018 commercialization of the rather remarkable Febreze One package with its Flairosol dispensing technology. Winner of a Diamond Finalist Award in the 2018 Dow Awards for Packaging Innovation, the package consists of an injection-/stretch blow-molded PET container, a full-body shrink-sleeve label, a sprayhead/dip tube/compression chamber, and an inner polyethylene bag holding 300 mL of liquid product that gradually collapses around the dip tube as product is dispensed so that minimal product is wasted. Be sure to visit pwgo.to/5314 for a complete description of the many benefits this innovative format delivers. The point to be made here is that once P&G’s Home Care Business Unit successfully commercialized Flairosol dispensing technology with Febreze One, it looked for other landing strips in its own portfolio of brands where the technology might successfully touch down. And so it was that Mr. Clean: Clean Freak Deep Cleaning Mist was launched in a 16-oz version of the Flairosol format. Like Febreze One, it comes in a “starter kit” consisting of one filled container with spray head attached. Displayed on shelf beside the starter kit are refill containers that have a simple threaded closure on top. The spray head does not go into the landfill. Consumers twist it off and twist it onto a refill container. As P&G’s Su Chang, Associate Director, Global Home Care R&D, told us in describing the Febreze One package, “The spray head is designed to be used thousands of times. It’s a complex piece of engineering and a high-performance piece of this particular packaging execution.” Adds Fish, “This is an important packaging platform that we’re going to leverage.”

In showing us the Clean Freak package, the design freak in Chief Design Officer Duncan can’t help but point out one more feature on the Mr. Clean package. “One of the biggest in-store consumer desires with a cleaning product like this is to know before making a purchase what the product smells like. So we addressed that desire by designing a squeeze-to-smell feature in the cap.”

External commercialization strategy

Returning to AeroFlexx for a moment, the third application of this award-winning technology is worth noting because it involves a brand that is decidedly not one of P&G’s. It’s Mighty Mutt dog shampoo, which is sold by Denver-based Blue Zebra Brands as an e-commerce play. Mighty Mutt’s shampoo is packaged by a Chicago-based company called Innventure, a team of experienced professionals with a history of entrepreneurship that partners with firms on a contract basis. “Innventure will scale this AeroFlexx technology under a global licensing arrangement to make this a broader industry play and not just a unique P&G item,” says P&G Research Fellow Ken McGuire, who played a key role in the development of AeroFlexx. Chief Research, Development and Innovation Officer Fish explains the strategy behind this external commercialization activity.

This application of AeroFlexx technology is especially interesting because it involves a brand that is not P&G’s. The dog shampoo is packaged by Innventure, a Chicago-based team of entrepreneurs that is licensed to scale AeroFlexx technology through external commercialization.

This application of AeroFlexx technology is especially interesting because it involves a brand that is not P&G’s. The dog shampoo is packaged by Innventure, a Chicago-based team of entrepreneurs that is licensed to scale AeroFlexx technology through external commercialization.

That brings us to PureCycle, another potentially breakthrough packaging technology developed internally by P&G scientists that is now being commercialized for use by an external company. Once again that external company is Innventure, as PureCycle Technologies is a portfolio company of Innventure. P&G’s scientists, however, continue to perform the R&D function for both PureCycle and AeroFlexx as Innventure rolls them out into the marketplace.

PureCycle, according to its website, is a “patented process that separates color, odor, and any other contaminants from plastic waste feedstock to transform it into ultra-pure recycled polypropylene. This process fully closes the loop in the reuse of recycled plastics while making recycled plastics more accessible at scale to companies desiring to use a sustainable, recycled resin.”

In 2017 PureCycle Technologies broke ground on a $120 million facility in Ironton, OH, about 120 miles from Cincinnati. The first step is to build a feedstock evaluation unit, and the second step is to develop a commercial-scale PureCycle facility. John Layman, a Ph.D and Section Head Corporate R&D Materials Science, is the founding inventor of PureCycle. He says he expects to see a container made of this recycled PP on a store shelf no later than some time in 2022. “I’d like it to be tomorrow,” he adds. “But we’ll get there. We wouldn’t have taken it as far as we have if we didn’t believe there was a way to commercial viability in terms of a sustained, profitable business selling the purified material.” For more on PureCycle, read my First Person interview here.

While AeroFlexx and PureCycle are similar in that both are examples of P&G externally commercializing new technologies that were developed internally, there is one difference between the two. AeroFlexx is viewed as a technology that should provide measurable licensing revenue, so P&G supports it both because it strikes a blow for sustainable packaging and because it represents a revenue stream. With PureCycle, on the other hand, it’s not just generating revenue that is a priority but rather making PP a widely accepted part of the circular economy.

“The revenue from PureCycle will likely be relatively small in the short term,” says Aguilar. “Our real interest is in protecting the ability to create beautiful packages that can be recycled. And you can only do that by changing the entire industry. Otherwise you’ll see the challenges on plastics, which is underway in Europe now, continue to spread. The last thing we want is to move from beautiful packages to ugly packages that don’t protect the product and don’t create the experiences we’re looking for just because of a classification of what can or can’t be recycled. Making recycled polypropylene widely available to the industry is how P&G wins.”

Just about everyone we talked with in our day at P&G agreed that sustainability is a top priority where packaging is concerned. And while PureCycle is one of the more ambitious sustainable packaging initiatives in which the firm has invested, it’s far from the only one. P&G is also a leading player in Loop. Led by TerraCycle’s Tom Szaky, Loop is aimed at allowing consumers to purchase products online in reusable packaging that is returned to Loop for cleaning and reuse when the product is consumed. (To get the full Loop scoop, we refer you to our coverage in the March issue: pwgo.to/5163.)

“Loop is an essential experiment for us, because one of the most important dynamics in the evolution of our packaging is the whole notion of sustainability,” says Duncan. “With Loop we’re learning who is the consumer to whom this would appeal. How do you design a package to win in the Loop environment? What does ‘winning’ mean in such an environment?”

Fish agrees that Loop is important, adding that, like all things in the sustainable packaging sector, “The consumer is only willing to suffer just so much pain for the good of the environment. We have to make it work for them.” (For more on P&G’s long-term sustainability plans and vision, see P&G Ambition 2030: pwgo.to/5315.)

Dealing with DTC

So what about e-commerce, which joins sustainability near the top of the list of packaging issues to be addressed by P&G? Pundits in Forbes and elsewhere have suggested that blue chips like P&G, Unilever, and General Mills are being nibbled to death by Direct-to-Consumer startups like Dollar Shave Club, Harry’s, Glossier, and others. Why? Because, say the pundits, the blue chips are actually B2B companies that serve the needs of retail businesses first while the Dollar Shave Clubs of the world are truly B2C companies focused not on the requirements of retailers but rather on the consumer. P&G leadership, however, believes it has a firm grasp of what it needs to do when it comes to e-commerce.

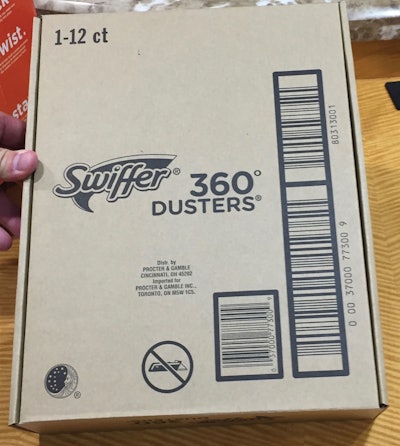

Packaging for this Swiffer offering that is delivered via e-commerce is one good example of how successful P&G has been in designing what’s known as SIOC—Ships In Own Container.

Packaging for this Swiffer offering that is delivered via e-commerce is one good example of how successful P&G has been in designing what’s known as SIOC—Ships In Own Container.

“If you think about it,” says Fish, “a lot of what we innovate for our retailers goes through bricks and mortar as well as e-commerce. So a lot of what you’ll see from us will be omnichannel in nature.”

Packaging for this Swiffer offering that is delivered via e-commerce is one good example of how successful P&G has been in designing what’s known as SIOC—Ships In Own Container.

Packaging for this Swiffer offering that is delivered via e-commerce is one good example of how successful P&G has been in designing what’s known as SIOC—Ships In Own Container.

Two such brands are SeeMe Beauty, a skincare line for women over 50, and Pepper & Wits, products for women coping with menopause. Both are e-commerce only. But the formation of P&G Ventures isn’t the only initiative taken by P&G where e-commerce is concerned. Tide Eco-Box is a brilliant execution of precisely the kind of package that Amazon is asking brand owners to develop for e-commerce shipment: SIOC, or Ships In Own Container (for details of this award-winning package, go here pwgo.to/5316). And it’s worth noting that this packaging innovation, winner of a 2019 Diamond Finalist Award in the Dow competition, was led not at the corporate level but by a team of people within the Fabric Care business unit that included the following: Sundar Raman, Vice President North America Fabric Care; Isaac Hellemn, Brand Manager for eCommerce Innovation Fabric Care; and Ty Martin, Associate Director R&D Packaging Fabric Care.

Countless other examples of P&G packaging designed for e-commerce are in development or emerging as we speak. Like the Swiffer 12-count corrugated SIOC shown on the facing page. For the purposes of this story, we’ll let Hellemn of the Fabric Care business unit sum it all up:

“E-commerce isn’t a trend anymore, it’s a reality, and we’re excited to keep innovating for it.”

Don’t forget the millennials

When asked about developing packaging that resonates with millennials, Fish says you have to begin with a willingness to listen and learn what it is they want. “What we’re learning is that they want more transparency, they want more simplicity, they want you to tell them exactly what a product is going to do, right? We’re hearing a lot of noise about how, with millennials at least, big brands are dead. But we’re finding that if we take what we learned about what millennials want and build it into our big brands and get those brands more on trend with where consumers are going, those brands do great. We’ve totally rejuvenated Olay, for example, which people were concerned was tired or was your mother’s brand. But it’s growing like crazy here in the U.S. and Asia, too.”

Duncan is especially pleased with how receptive Chinese millennials have been to a line of Olay products called CELLSCIENCE, which is only sold in Asia. Pointing to the packaging, he emphasizes how important it is to get it right where CMF is concerned—Color, Material, Finish. “With the red and the gold colors we were trying to elevate the superiority, the irresistible superiority, and cue the premium-ness of the product. The choice to use glass was significant, too, as we had not been using glass much in that space. But again it says premium.”

Beckett Ridge Technical Center

About 20 miles north of P&G’s Cincinnati headquarters is Beckett Ridge Technical Center, or BRTC as P&G calls it. Sitting on about 50 acres and employing some 600 of the 97,000 employees the firm employs worldwide, the buildings on this corporate R&D campus feature more than 606,000 sq ft of space. P&G had been leasing the buildings since they were built in 1998. In August of 2016, viewing the facilities as strategic R&D facilities that were better owned than leased, the firm bought the properties.

At Beckett Ridge Technical Center, Victor Aguilar, Vice President Corporate Technology Development and Open Innovation, shows how clean and white polypropylene flakes are once they’ve gone through the PureCycle process. Looking on is P&G Research Fellow Ken McGuire.

At Beckett Ridge Technical Center, Victor Aguilar, Vice President Corporate Technology Development and Open Innovation, shows how clean and white polypropylene flakes are once they’ve gone through the PureCycle process. Looking on is P&G Research Fellow Ken McGuire.

There’s also a large, high-ceilinged space in which to install whatever newly invented equipment P&G’s scientists, engineers, brand managers, and designers come up with. Power, air, and all the utilities needed for a Consumer Packaged Goods company to make and package its products are in place and can be dropped down from the ceiling. “What that high-bay area allows us to do is assemble things in the lab, test them out, run them for as long as we like, and then take them apart and put the next new innovation idea in,” says McGuire.

Among the capabilities in place at BRTC are these:

• Pilot-scale film lines, both blown and cast. “This is where we do a lot of our sustainable packaging materials development,” says McGuire. “We can create structures here with polymers and other things that are new to the world. Once we get a structure we want to commercialize, we work with an outside vendor to produce it for us. But we retain the IP. We own the know-how.”

• A fully equipped mold-making shop.

Febreze Air Freshner

Febreze Air Freshner

• Injection molding machines. These paved the way recently in the development of ISBM PET bottles for Rejoice brand shampoo, sold in Asia, and an Herbal Essences bottle sold in the U.S. (See sidebar below.)

• Pop-up labs dedicated to exploring specific opportunities.

One of these pop-up labs played a key role in advancing the AeroFlexx technology. “The early prototypes were not very good, frankly,” says McGuire. “Part of the problem is that it took too long to make them because we were making them with heat-seal dies. Those are made from plates of aluminum or steel, which means they take forever to make. We needed a way to speed up our prototyping capability, so we built this lab and equipped it with a super-cool tool that does heat sealing without cumbersome heat-seal dies. It’s like a gigantic plotter that’s used in printing. But instead of running paper beneath a programmed stylus that prints, the stylus is replaced by a heated piece of aluminum. It traces out heat-seal patterns on pieces of plastic film. So now we create in 2D CAD the heat-seal pattern we want and transfer that file to the plotter. It lets us make 30 or 40 prototypes a day instead of one every two weeks. It’s a good example of what we do here at BRTC if we see an opportunity that’s promising. We build and equip a lab to explore it.”

Elsewhere on the tour of BRTC McGuire points to another advanced piece of equipment that helped catapult AeroFlexx forward: a laser cutter. “This is a piece of equipment we bought specifically for the AeroFlexx project,” says McGuire. “We had been doing mechanical perforation for the tear-off top, but it meant we had to walk a very fine line between poking a hole in the material that would cause a leak in transit or not making a deep enough cut to allow the consumer to tear the tab conveniently. Creating the perforation by laser gives us so much more control.”

Once the laser cutter was installed, it dawned on McGuire and others at BRTC that laser technology was something that should be explored further. So four additional laser systems were installed in a newly created laser lab. “What better way to explore how laser technology can be used in packaging, whether it’s functional or decorative?” asks McGuire.

The laser lab is a good example of P&G’s seed fund program. “It’s a program inside the packaging organization where younger technologists can submit an idea for something they want to work on,” says McGuire. “These are screened, and then three or four of them each year are chosen to be funded at the corporate level. The younger technologist is partnered up with a senior technologist who’s been around for a while.”

The idea for the laser lab came from a P&G Principal Engineer who has been at P&G since graduating from the Mechanical Engineering department at the University of Dayton in 2005. Spend a few minutes talking with him about laser technologies in the femtosecond region and you know he’s found the lab in which he belongs. He also makes an interesting observation about BRTC. “Surrounded as we are by all these really cool capabilities, we sometimes find packaging innovation at the seams of the various technologies. For example, what happens when you start thinking about lasers knowing you have both a stretch blow and an injection molding machine right down the hall? We’re able to bring such technologies together and look for something unique at the seams.”

This kind of thinking reflects a company-wide dedication to delighting the consumer by delivering a superior experience. “It starts with product and package at the foundation,” says Chief Research, Development and Innovation Officer Fish. “But then we ask ‘How do we make the consumer really love this?’ Not just because it’s functional and does what it needs to do, but because we’ve made it irresistible.”

For more on P&G, go to https://www.packworld.com/21104288