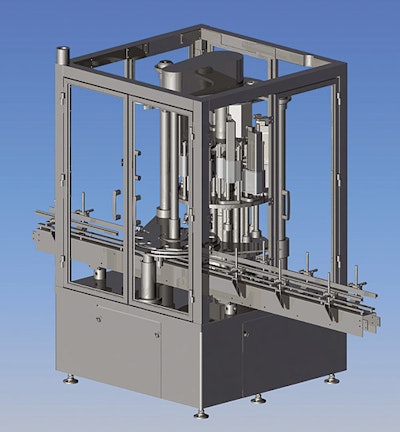

New from the inside out, Pneumatic Scale’s Series SC capper is said to be the first servo-driven capper from a United States manufacturer. The machine’s controls components, from Elau, include servo motors and drives and a PacDrive® controller that integrates logic and motion control.

The machine culminates a 10-year wait for vice president of engineering Mike Mihalik of the Cuyahoga Falls, OH machinery builder. “We’ve been waiting that long for the right servo technology,” says Mihalik. “The PacDrive is uniquely designed for rotary turrets to make communications and wiring much simpler.” It can handle up to 99 servos and 200 input/outputs, according to Elau.

Available in several models, the capper is as distinguished by what it doesn’t have as by what it has. What it doesn’t have is a large main gear that drives the spindles that screw down the caps. It also has 15% fewer parts and half the wiring of mechanical models. And there’s no magnetic clutches that characterize most capping machines.

Its servo-driven design greatly improves torquing accuracy, which has dropped from 10% all the way down to 0.5%.

“Tighter application torque produces better removal torque,” Mihalik points out. “End users will see fewer loose caps and leakers and fewer caps that are ‘impossible’ for consumers to get undone.”

It even offers torque profiling, which Mihalik says permits users to pinpoint torquing programming for individual heads. That means the capping process can be optimized for the particular cap and container.

Other machine highlights:

• Modularity simplifies any upgrades or add-ons

• Torquing is independent of machine speed

• Servo-driven capping spindles are monitored and can be adjusted individually

• Feedback provides data on each and every cap

• Tool-less changeovers should take 10 to 15 minutes

• Improved diagnostics include remote troubleshooting capability

• Predictive maintenance is simplified

• Communications via SERCOS (internal) and Ethernet (external) are both standard

The machine can also be run in sample mode. Thus, torqued containers can be reverse-torqued to measure the actual torque, and then the caps can be reapplied and the containers discharged. For traditional machines, caps must be tested manually to determine the applied torque.

Data collection is built-in thanks to Pneumatic Scale’s own software along with the closed-loop nature of the servo-based system. Mihalik says their programming enhances the machine’s flexibility and statistical reports.

Although the PacDrive obviates the need for a programmable logic controller, Pneumatic Scale provides a PLC as standard for customers familiar with—and expecting—PLC logic onboard.

Mihalik feels the SC Series cappers, though suitable for any dry or liquid screw-cap application, will draw special interest from customers in pharmaceutical, cosmetics, and household chemical industries.

The cappers will be available for delivery in fall 2005 in three standard machine pitches—450, 600, and 900 mm—in versions from two to 24 capping spindles.