Anticipating the new technology at the show is one of the reasons I read with interest—and glee—a special report on American productivity called “The new ‘new economy’” in the September 13 issue of The Economist. Of course, this is a wide-ranging study of a whole series of analysis that tries to explain why productivity in America continues to grow, even in the face of lackluster investments.

In 1999, economist Robert Gordon of Northwestern University made a case that American productivity gains were concentrated in the manufacturing of computers, with no net gain in the rest of the economy, according to the report. Gordon went on to conclude that the economic effects of the computer and the Internet “were not in the same league as those of electricity or the motor car in the early 20th century.” (In a more recent paper, he admits data have proven his original conclusion to be wrong, the report says.)

However, the authors of The Economist article struggled to understand why American labor productivity has in fact speeded up since the peak of the economic boom in 2000. Especially in the face of falling investments in information technology, the productivity increases had economists scratching their collective head. After all, it pointed out that a whole host of studies showed that most of the revival in productivity growth was directly linked to the “production or the use of computers and software.”

The report included a sidebar reporting that automation is one part of productivity, but “better understanding is the key.” In one example, it showed that Procter & Gamble had previously determined the most efficient way to get detergent from warehouses to shop shelves was to load trucks as fully as possible. Then, after running a software program that simulated inventory management, the company learned counter-intuitively that it made more sense to send trucks less full of detergent and to load some other products alongside. The result of making that change is that P&G reports inventory is down by 30%, and warehouse workers have less idle time.

The good news is there are a lot of economic analysts, any of whom can provide part of the answer to the American productivity conundrum. One study by an Oxford University economist showed that productivity growth did not accelerate until years after the introduction of electric power in the late 19th century. So the theory goes, it takes companies some time to learn how to use new tools for improving productivity.

“So computers and the Internet are triggering a sweeping reorganization of business, from the online buying of inputs to the outsourcing of operations. Yet again,” the report concludes, “the benefits are arriving years after the money has been spent.” Maybe.

Another explanation—one that I can identify with—came from Stephen Roach of Morgan Stanley. Although official statistics say Americans in financial services keep the same office hours as a decade earlier, Roach argues that new high-tech tools (e-mail, cell phones, PDAs) have caused his workday to “surely lengthen over the past decade,” the report says. If so, concludes the report, “productivity growth may be overstated.”

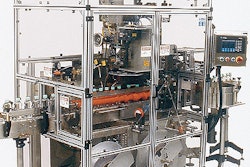

So, as we in packaging fold our garments and check our toiletries for our October trip, we recognize that increased productivity—maybe soon, maybe longer-term—is what we’re seeking for our companies at these gatherings. And the equipment and new materials we evaluate have only a slim connection to information-technology investments. Sure, the improvements we make may not represent “big-picture” change noticed by economists, but maybe a lot of smaller snapshots do add up, just like the software program at P&G.

See an archive of Arnie Orloski's Pipeline columns at www.packworld.com/pipeline.

Arnie can be reached at [email protected]